Learn the differences between ESD solid vinyl tile and interlocking ESD tile. The post compares specs, installation, maintenance and intangibles.

8 Reasons ESD Programs Fail

10 min read

A well-designed, comprehensive, fully realized program is a must for manufacturers serious about ESD control.

What do these firms get for their money?

Some organizations realize immediate improvements—both in yield and reduction of field returns. Others implement an ESD program only to solicit and retain contracts. Others know they need static protection but are not sure what they’ve gotten or why they’ve gotten it.

What do these firms get for their money?

Some organizations realize immediate improvements—both in yield and reduction of field returns. Others implement an ESD program only to solicit and retain contracts. Others know they need static protection but are not sure what they’ve gotten or why they’ve gotten it.

Failed programs are often doomed from inception

The cause, effect, and solution to ESD problems is widely accepted and well documented. Why, then, is it so difficult to adhere to a comprehensive in-house static-protective program?

Some ESD programs do not measure up to the anticipated objectives; others are completely ineffective. When programs do fail it’s often because they were doomed from inception.

A major manufacturer of computer peripherals was quite proud of its ESD program and was not shy to point out its considerable expenditure. An audit became necessary when new gate arrays used in a recently-introduced product failed at an astounding rate. Field returns were eating away at profits and at the company’s hard-earned reputation.

A thorough investigation uncovered numerous broken links in a chain of protection dependent upon total continuity.

A film about “zaps and zings”

The audit confirmed that the wrist straps, conductive containers, dissipative table mats, and ionizers the company used complied with guidelines set by their prospective customers. However, half the wrist straps failed a simple continuity test, and many that did pass were either connected improperly or worn too loosely to ground the wearer reliably. The ESD floor finish on their VCT floors was several months old and no longer complied with ANSI/ESD requirements. The ionizer blowers contained enough dust and dirt to allow only a whisper of the original air flow to pass through them. The tote boxes, originally supplied with lids, were left uncovered because the lids were cumbersome and did not appear to serve any purpose beyond that of dust collector.

When questioned about ESD training, most assembly people said they recalled viewing “some film about zaps and zings.”

This example is not an isolated circumstance. It is not uncommon for manufacturers to feel that the success or failure of an ESD program is based solely on the amount of money they’ve invested. What they often do not realize is that for any ESD program to be successful, there are a number of factors that need to be addressed before implementation. If obstacles recognized in advance cannot be resolved the project should not be undertaken. In most cases, though, the obstacles that lead to failure can be avoided, sometimes before a single nickel is wasted.

The audit confirmed that the wrist straps, conductive containers, dissipative table mats, and ionizers the company used complied with guidelines set by their prospective customers. However, half the wrist straps failed a simple continuity test, and many that did pass were either connected improperly or worn too loosely to ground the wearer reliably. The ESD floor finish on their VCT floors was several months old and no longer complied with ANSI/ESD requirements. The ionizer blowers contained enough dust and dirt to allow only a whisper of the original air flow to pass through them. The tote boxes, originally supplied with lids, were left uncovered because the lids were cumbersome and did not appear to serve any purpose beyond that of dust collector.

When questioned about ESD training, most assembly people said they recalled viewing “some film about zaps and zings.”

This example is not an isolated circumstance. It is not uncommon for manufacturers to feel that the success or failure of an ESD program is based solely on the amount of money they’ve invested. What they often do not realize is that for any ESD program to be successful, there are a number of factors that need to be addressed before implementation. If obstacles recognized in advance cannot be resolved the project should not be undertaken. In most cases, though, the obstacles that lead to failure can be avoided, sometimes before a single nickel is wasted.

The Eight Most Common Reasons Why ESD Programs Fail

1) Little support from top management

The most common reason ESD programs fail is the lack of visible support by top management.

Most engineers seek management’s support before soliciting capital funding for a project. But the appropriation of funding should be the tip of the iceberg when it comes to management’s role in developing a successful ESD program.

Management needs to show, by example, that everyone— CEO and customers included—must exercise the precautions specified by the resident ESD program manager.

To be successful, ESD prevention requires teamwork— achieved through consistency, dedication and measurable objectives—between all levels of the organization.

The most common reason ESD programs fail is the lack of visible support by top management.

Most engineers seek management’s support before soliciting capital funding for a project. But the appropriation of funding should be the tip of the iceberg when it comes to management’s role in developing a successful ESD program.

Management needs to show, by example, that everyone— CEO and customers included—must exercise the precautions specified by the resident ESD program manager.

Management shows support by appearing at training seminars and by giving a brief preliminary pep-talk relating the features and benefits of the ESD program and the impact each individual will have upon it. Management should also recognize departments with satisfactory records of ESD prevention and should provide assistance for those departments that fall short of the mark.

To be successful, ESD prevention requires teamwork— achieved through consistency, dedication and measurable objectives—between all levels of the organization.

2) Taking a band-aid approach as opposed to implementing a permanent solution

Many ESD programs appear to have been based on the theory that there is never time to do it right, but there is always time to do it over. Faced with budgetary constraints, many companies employ spot solutions rather than taking a long-range look at their options. Examples include:

- Failing to view ESD as a systemic problem—e.g., creating spotty static-free islands rather than investing in a continuous ESD floor.

- Using small table mats rather than covering the entire workbench surface.

- Recycling disposable shielding bags as opposed to using durable, reusable trays and boxes.

- Purchasing fragile soft table mats rather than permanently installed work surfaces.

- Installing ground cords with easily disconnected snaps or low-gauge wire that will break after its first encounter with a tote box.

- Neglecting to evaluate ESD-prevention equipment based on ANSI/ESD S20.20 requirements—e.g, not testing electrical contact between mobile workstations and carts to the ESD floor ground connection.

However big or small the investment, ESD-preventive measures should be installed correctly the first time — when the cost is lowest. It is far less expensive to static-proof the environment (i.e., the floors, tables, footwear, and material-handling system) than to employ and monitor band-aid solutions that will soon require costly repairs or replacement.

3) Poor training or no training at all

Most companies are not prepared to train the entire work force effectively in the dos and don’ts of static control. A survey of 50 electronics companies found that most training programs required attendees to watch a film about ESD in a crowded room followed by a brief explanation of the features and benefits of static control. Many of the companies surveyed limited mandatory attendance at training seminars to assembly-level personnel.

When it comes to personnel, effective static control is an all-or-nothing proposition. To thrive (and provide payback), the program should be a priority for every employee of a corporation. The CEO can destroy a sensitive component with the same ease as the night janitor.

Many dollars are wasted on high-quality ESD-prevention equipment that isn’t tested regularly, is used improperly by ill-informed personnel and/or is purchased based on incorrect technical assumptions. If specifiers are not ESD experts or in-house trainers cannot develop a convincing and informative seminar, it would be wise to seek outside assistance.

4) No follow-up after program implementation

Many ESD-prevention items require periodic functional testing, occasional maintenance and, in some cases, replacement. Wrist straps become ineffective when insulative skin oils build up between the wearer’s wrist and the conductive fabric. Unless a continuous daily testing program is in place, bad wrist straps could be in use for weeks or even months. Static bags wear out and should be replaced. Dirty conductive casters on mobile carts become insulative and prevent static charges from dissipating to the grounded ESD floor.

The importance of proper maintenance and training reinforcement cannot be overemphasized. The reliability of any ESD program depends upon constant monitoring and fine-tuning where necessary. ESD programs are most successful when one individual is delegated management responsibility. His or her authority must be supported by supervisors and recognized by fellow employees. In regards to training, employees frequently require further education and positive reinforcement regarding their role in the ESD program.

Many ESD-prevention items require periodic functional testing, occasional maintenance and, in some cases, replacement. Wrist straps become ineffective when insulative skin oils build up between the wearer’s wrist and the conductive fabric. Unless a continuous daily testing program is in place, bad wrist straps could be in use for weeks or even months. Static bags wear out and should be replaced. Dirty conductive casters on mobile carts become insulative and prevent static charges from dissipating to the grounded ESD floor.

Companies that take ESD seriously always invest in test equipment to calibrate and monitor the performance of their ESD-preventive equipment. At bare minimum, every company should own resistance and static field measuring equipment that enables testing of equipment and materials per ANSI/ESD S20.20.

The importance of proper maintenance and training reinforcement cannot be overemphasized. The reliability of any ESD program depends upon constant monitoring and fine-tuning where necessary. ESD programs are most successful when one individual is delegated management responsibility. His or her authority must be supported by supervisors and recognized by fellow employees. In regards to training, employees frequently require further education and positive reinforcement regarding their role in the ESD program.

5) Programs implemented only to placate the customer

Quality-conscious organizations and corporations require all suppliers and subcontractors to maintain a static-free environment. Compliance is usually confirmed by an ISO audit or sometimes by a visit from a vendor engineer. During this visit, the “auditor” evaluates the static-preventive measures specified by the particular contract against industry standard ANSI/ESD S20.20. Noncompliance can result in a failure to become ISO certified or the withdrawal of a contract.

Short-sighted management teams sometimes implement an ESD program purely for the purpose of satisfying a vendor audit. The “solution” is often a hastily-installed program using the least expensive materials available. It is not uncommon for such organizations to slap an ESD program together several times a year. Preventive maintenance, follow-up, and training are virtually nonexistent.

Often, at the insistence of accounting – those most interested in eliminating costly throw-away solutions – the problem is eventually corrected. A solid understanding of the problem, coupled with the commitment to a long-term solution, is essential to establishing a dependable and worthwhile ESD program. In the long run, a well-planned, properly implemented ESD program easily pays for itself through improvements in quality, reliability, and reputation.

6) Over-reliance on the manufacturer’s specifications

It is important to note that products or equipment that behave one way under controlled conditions may perform differently in a factory environment.

ESD product manufacturers almost always state compliance with industry standards. However, the tests they reference on their spec sheets are performed in controlled environments that can differ significantly from the factory where the product/s will be used. That’s why it’s wise to test any proposed ESD product or equipment in the lab and under in-house factory conditions.

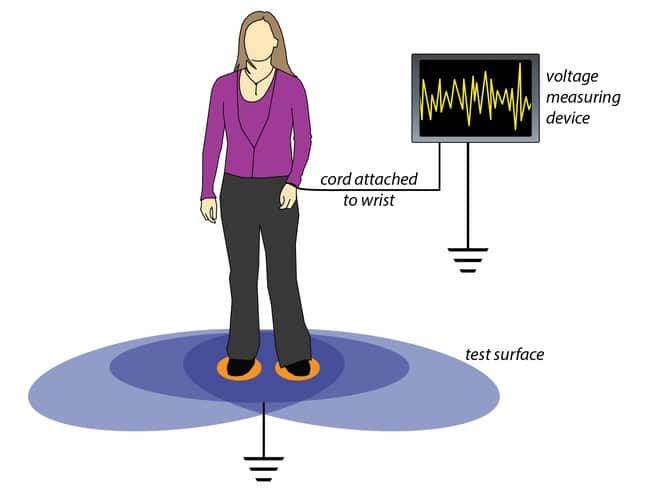

When comparing products, rather than simply using the manufacturers’ specifications, it is imperative to obtain a copy of the industry standard and determine the parameters of the test. For example, when testing an ESD floor most prospective buyers only measure the resistance of the floor. To prove compliance with ANSI/ESD S20.20, a floor must also be tested for walking body voltage generation. Because footwear influences performance, ESD floors must be tested in conjunction with a person wearing whatever footwear will be allowed for use in the space.

ESD product manufacturers almost always state compliance with industry standards. However, the tests they reference on their spec sheets are performed in controlled environments that can differ significantly from the factory where the product/s will be used. That’s why it’s wise to test any proposed ESD product or equipment in the lab and under in-house factory conditions.

When comparing products, rather than simply using the manufacturers’ specifications, it is imperative to obtain a copy of the industry standard and determine the parameters of the test. For example, when testing an ESD floor most prospective buyers only measure the resistance of the floor. To prove compliance with ANSI/ESD S20.20, a floor must also be tested for walking body voltage generation. Because footwear influences performance, ESD floors must be tested in conjunction with a person wearing whatever footwear will be allowed for use in the space.

7) Failing to deal with reputable suppliers

For many companies, price still largely determines the selection of both product and vendor. Little consideration is given to either the reliability of the vendor or the range of services he or she is prepared to supply. At times, even the quality of materials is overlooked in the quest for low-budget solutions.

Neglecting to investigate a vendor’s credentials can sink a well-intended program, regardless of cost.

It’s easy to identify reliable vendors by selectively screening their customer base and closely examining their products. For example, before selecting an ESD floor it’s always a good idea to install a mock-up area. Mock-ups help identify unanticipated issues like cart-to-ground resistance problems, durability, and rolling load concerns. Flooring mock-ups help eliminate problems such as choosing the wrong color or selecting a pattern that would make it difficult to find small parts that have been dropped on a floor.

Vendors should be prepared to speak knowledgeably on how their products integrate with an ESD program, including installation, grounding , maintenance, calibration, and post-installation testing.

8) ESD control is limited to the manufacturing environment

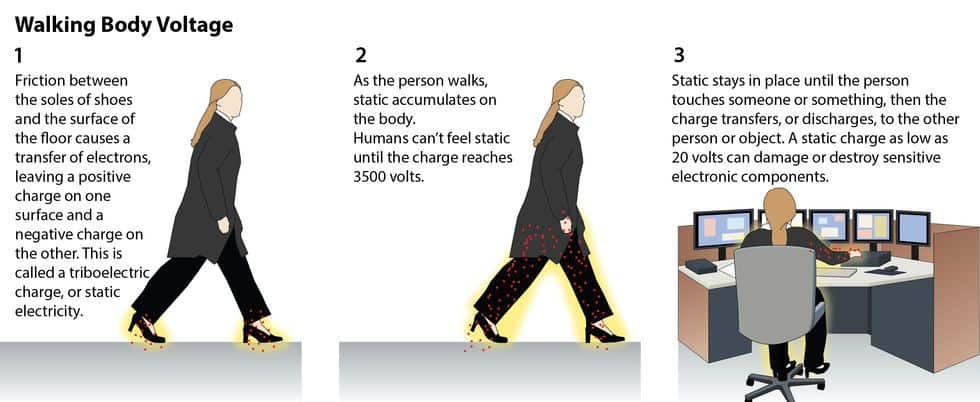

Sensitive electronic parts are still vulnerable to damage in the environment of the end user—the customer. Once outside the manufacturing facility, components are subjected to static-charged environments. Ill-informed users within these environments may be unaware of the thousands of volts of potentially destructive static they carry when seated in a static-generating chair or walking on a high-charging floor.

Despite hazardous and potentially crippling conditions, the problem remains unrecognized, often leading to redundant field service calls, excessive downtime, and conceivably, loss of the customer.

Manufacturers should provide ESD guidelines for environments where their equipment will be used. If their products are designed for critical environments or 24/7 public safety operations – where people do not wear ESD-protective footwear – the manufacturer should offer guidance regarding the types of static-control floors and furniture that might be used to mitigate potential ESD events.

Conclusions

Controlling ESD is a matter every electronics company must confront. Maintaining a competitive edge in today’s marketplace can hinge on an organization’s ability to deal successfully with the fundamental but invisible static discharge phenomenon.

The problem, while certainly not insurmountable, demands a formidable opponent in the form of a well-organized, comprehensive static-protection program. Successful ESD programs depend on careful planning by conscientious individuals, with precise implementation, effective training, and thorough follow-up, originating at the top, moving through the assembly line and progressing straight to the customer.

About StaticWorx, Inc

All StaticWorx posts are written by our technical team and based on industry standards and specifications, test data, independent lab reports and other verifiable data. We provide ESD training and offer CEU credits to architects. If you’re interested in an ESD training session or our architects’ ESD workshop, give us a call: 617-923-2000.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

More Blog Posts

To maintain performance, ESD floors require specially formulated products. We offer tips on what to consider when choosing cleaning supplies.

Static-dissipative floors transport harmful static charges to ground. Dissipative is also a term for flooring with a specific, measurable electrical resistance.

StaticWorx recognized as one of the fastest growing private companies in the U.S. 2023 marks StaticWorx fourth appearance on Inc. 5000 list.

Conductive and dissipative flooring protect electronics by transporting charges to ground, conductive at a quicker rate, dissipative slower & more controlled.

We explain the 3 main ways to test an ESD floor: Electrical resistance; body voltage & ESD audits, with advantages and reasons for each.

Three critical factors—application, industry standards & footwear—help you choose the best ESD floor, while ensuring the safety & efficiency of your operations.

StaticWorx Founder and President Dave Long shares three of his recommended reads: Quit, How to Change, and The Goal.

There are leadership qualities StaticWorx strives to embody every day, with every product, throughout each project.

No matter how you slice and dice a project, an ESD floor is a major investment. This blog post examines five ways to keep undue costs down.

What’s the difference between static control and static resistant? Or anti-static flooring? Find out more in our blog post.

A major part of any ESD control program is getting proper flooring in place. How can one replace a floor without generating any debris? Learn more.

ESD Floors should never be specified based on the descriptive terms conductive or static dissipative. Always base ESD specs on verifiable metrics. Find out why.

To comply with relevant ESD standards, test electrical properties using methods outlined in ESD S20.20. For best results require testing by an independent lab.

If the vapor barrier fails to adhere to the subfloor, tiles will lift. Bond test and manufacturer oversight are crucial to ESD floor installation success.

Blog Post: Conductive and Static-Dissipative Flooring: What’s the Difference?

The Layperson’s Answer

What’s the difference between conductive and static-dissipative flooring? Facts, analogies and images illustrate the difference in easily understood terms.

Qualifying an ESD floor helps ensure you get the floor you paid for. Find out why you should always qualify according to ESD S20.20

Qualification is the first step in selecting an ESD floor. Learn how to perform resistance tests to be sure the floor meets electrical & safety standards.

Will bare concrete control static? Learn why concrete floors are unreliable & what precautions to take if you must work on a bare concrete floor.

A look at how the StaticWorx cartoon, 'Conductive Flooring Does Not Mean Antistatic Flooring,' was conceived and created.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.