What is Walking Body Voltage?

[12 min read, 11 min videos]

Walking Body Voltage and Low Charge Generation

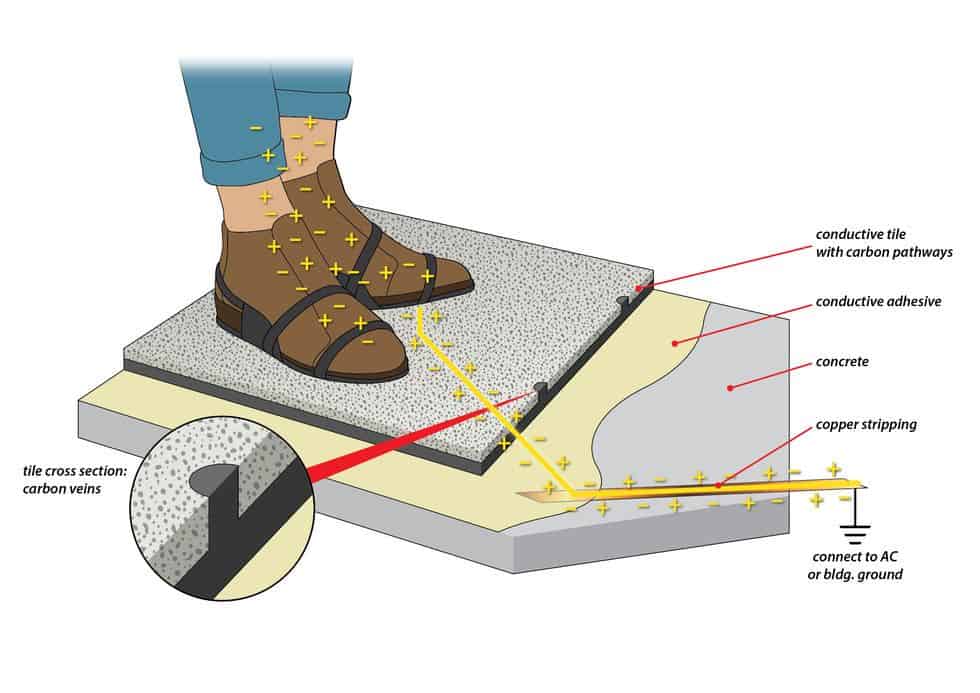

Conductivity—a floor’s ability to ground static charges—is only one property of an effective ESD floor. A floor may ground charges safely and quickly, but if it doesn’t prevent static from building on people as they walk (walking body voltage), the floor will not prevent ESD events.

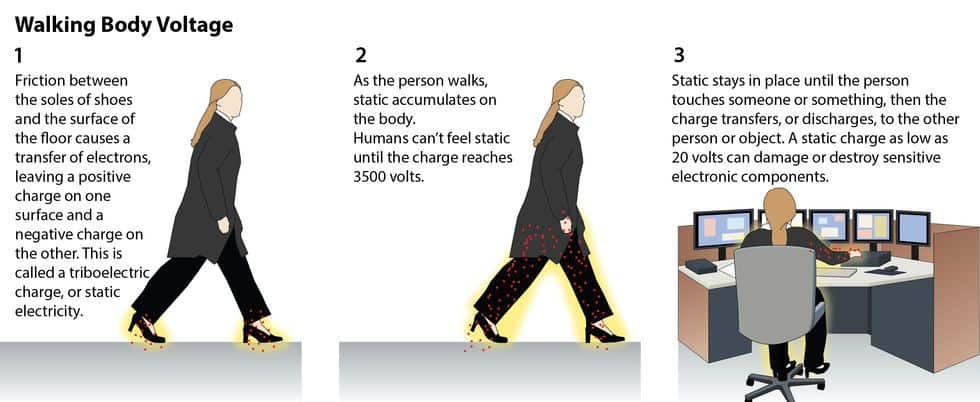

When people walk across a floor, the friction between the soles of their shoes and the surface of the floor generates a triboelectric—or static—charge, also called walking body voltage.

The charge stays in place until the person touches someone or something, then it jumps to that person or object. This sudden rush of electrical current—like a zap from a tiny lightning bolt—is called an electrostatic discharge, or ESD. Minute static events, far too small for humans to perceive, can wreak havoc in any environment where electronic components are manufactured, assembled, handled or used, and can even shut down entire operations.

Some, though not all, ESD floors prevent the accumulation of static as people walk. Floors that perform this function used to be called antistatic. Recently, because the descriptor is more accurate, floors that inhibit charge generation were renamed low charge generating.

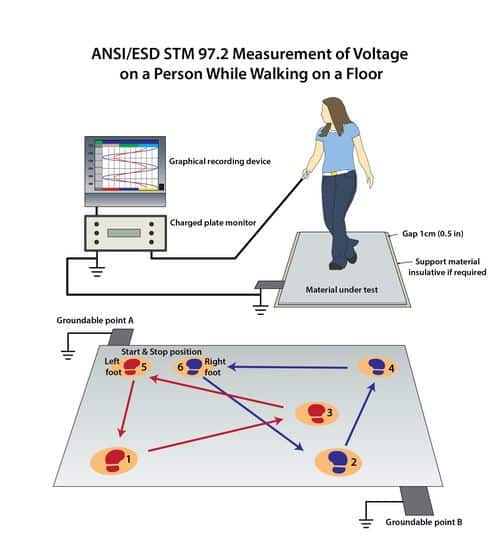

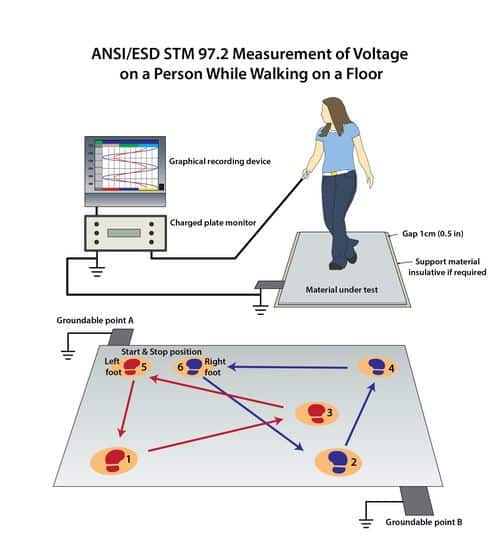

Industry Standard for Charge Generation: Walking Body Model

Current ANSI/ESD static-control test methods require that charge generation tests be conducted with the subject wearing the exact types of shoes that will be worn by people walking on the static-control floor. For example, if people will wear a certain brand of heel straps the floor should be tested with that brand of heel straps – not another type of strap.

This also means, if people working in or walking through the environment will be wearing street shoes, then the floor should be tested for charge generation on people wearing a variety of types of street shoes.

* Many flooring manufacturers continue to present performance criteria solely on conductivity—even though charge generation test requirements have mandated in ANSI/ESD standards since 2014.

Current ANSI/ESD static-control test methods require that charge generation tests be conducted with the subject wearing the exact types of shoes that will be worn by people walking on the static-control floor. For example, if people will wear a certain brand of heel straps the floor should be tested with that brand of heel straps – not another type of strap.

This also means, if people working in or walking through the environment will be wearing street shoes, then the floor should be tested for charge generation on people wearing a variety of types of street shoes.

* Many flooring manufacturers continue to present performance criteria solely on conductivity—even though charge generation test requirements have mandated in ANSI/ESD standards since 2014.

ESD Floors Should Be Grounded and Low Charge Generating

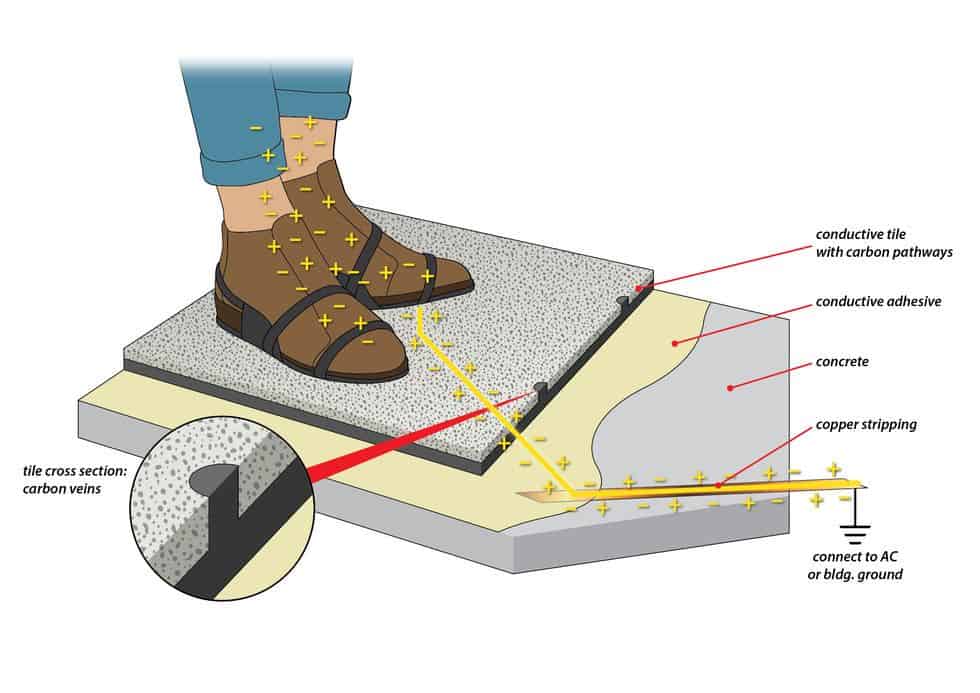

As noted above, providing a path to ground is an important quality of an ESD floor, but it’s only part of its job. Highly effective ESD floors perform two separate, equally important functions:

- Provide a safe, traceable pathway to ground; a resistance in the “sweet spot.”

- Prevent static charges from accumulating when people walk on the floor (walking body voltage). In other words, the floor should be low-charge generating.

ESD Floors Provide a Safe, Reliable Path to Ground

Many static-protective, or ESD, floors fail to meet both requirements.

ESD vinyl does an excellent job of discharging static to ground. But vinyl is an inherently insulative material; even with embedded carbon particles, vinyl will generate a charge. Unless every person in the facility wears static-protective footwear (heel straps, toe straps, or ESD shoes), ESD vinyl will not prevent charges from building as people walk. This doesn’t mean ESD vinyl is a poor choice for static protection; it does mean that for vinyl to eliminate static, protocols must be in place, mandating that everyone in the environment wears ESD footwear.

In environments, such as server rooms, 9-1-1 dispatch operations, FAA flight towers, or mission critical data centers, where people wear a variety of non-ESD footwear, rubber or static-dissipative carpet are the best ESD flooring choices.

How Does a Low Charge Generating Floor Inhibit Static Generation/ Walking Body Voltage?

It’s complicated.

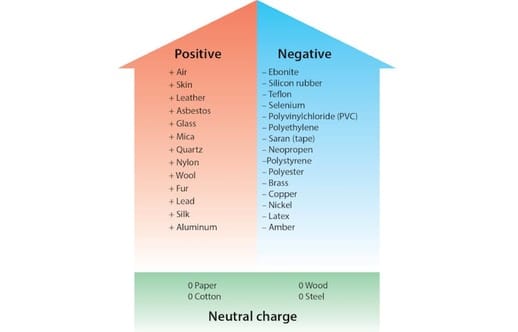

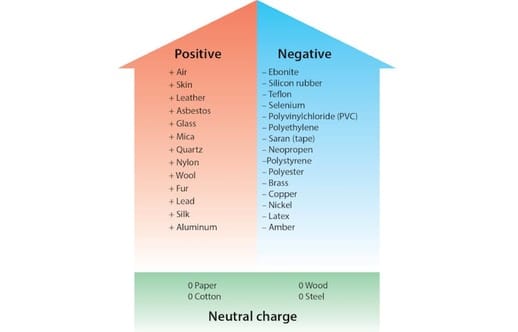

Tribocharging refers to electrical adhesion, or the way—when in frictional contact—different materials attract and exchange electrons. As shown on the triboelectric chart, different materials have different triboelectric effects.*

We know that whenever two chemically dissimilar materials rub together they generate static. The corollary is also true: materials with a similar chemical makeup generate less static when they interact.

For instance, the base compound used in two-layer ESD rubber sufficiently resembles most shoe soles to the point that an ESD rubber floor inhibits static on all types of footwear. Numerous lab tests and industry studies have proven static-control rubber to be a unique low-generating material, regardless of footwear.

Conductive and dissipative vinyl floor products, on the other hand, are made from ordinary static-generating plastic compounds, mainly polyvinyl chloride (PVC), with a small distribution of carbon or graphite particles. Due to vinyl’s poor triboelectric properties, when they walk on conductive vinyl people wearing ordinary footwear will generate significant static charges.

It’s complicated.

Tribocharging refers to electrical adhesion, or the way—when in frictional contact—different materials attract and exchange electrons. As shown on the triboelectric chart, different materials have different triboelectric effects.*

We know that whenever two chemically dissimilar materials rub together they generate static. The corollary is also true: materials with a similar chemical makeup generate less static when they interact.

For instance, the base compound used in two-layer ESD rubber sufficiently resembles most shoe soles to the point that an ESD rubber floor inhibits static on all types of footwear. Numerous lab tests and industry studies have proven static-control rubber to be a unique low-generating material, regardless of footwear.

Conductive and dissipative vinyl floor products, on the other hand, are made from ordinary static-generating plastic compounds, mainly polyvinyl chloride (PVC), with a small distribution of carbon or graphite particles. Due to vinyl’s poor triboelectric properties, when they walk on conductive vinyl people wearing ordinary footwear will generate significant static charges.

✓ visual selector guide;

✓ walking body voltage/low static generation;

✓ resistance requirements and testing;

✓ ESD flooring comparison;

✓ industry standards & test methods;

✓ key ESD terms

Why Do Some Floors Generate More Static Than Others?

Whether or not a floor will prevent static generation is determined by the triboelectric effects of the flooring material (or the material chemistry), the way the floor is manufactured, and how the flooring material interacts with the composition of the footwear people wear when they walk on the floor.

Flooring Materials

Floors like ESD vinyl and epoxy are made from base materials—usually PVC and polyurethane—that generate static.

Vinyl and epoxy floors prevent static generation only if they are properly grounded AND every person walking on the floor wears static-protective footwear. The conductive elements in ESD sole, heel or toe straps and ESD shoes form an electrical bond with the conductive elements in the floor, directing static charges away from the body, through the floor, to ground.

When interacting with regular footwear (the frictional contact that occurs when people walk on the floor), conductive and static-dissipative vinyl and epoxy floors will behave as if there were no carbon or grounding properties whatsoever.

Manufacturing

Some so-called “antistatic” or “low kV” carpets gain their static-protective properties from antistatic sprays that wear off over time. While they may generate very little static when new, low kV carpet generates significant static as the coating wears off.

The amount of conductive byproduct added to the flooring material can also influence performance. If there are too few conductive veins in the floor and the surface of the ESD footwear is too small (with toe straps, for example), there may not be enough contact (between floor and footwear) to form the necessary electrical bond, so the floor could still generate static.

Interaction with Shoe Soles

Some shoes generate less static than others. Leather soled-shoes, for instance, generate less static than shoes with static-generating PVC soles—athletic shoes, for example.

Due to its unique triboelectric properties, leather is an inherently low charge-generating material. Leather also tends to absorb moisture (from the air or from sweat), and water is conductive. If a person wearing leather shoes steps in a puddle, the shoes absorb moisture and the leather becomes more conductive. When the wearer walks on an ESD floor, the conductivity in the shoes will bond with the conductive elements in the floor and—like ESD-protective footwear—direct static charges to ground.

Note: This moisture effect is one of the reasons that ANSI/ESD tests require conditioning footwear at low humidity for 48 hours before performing walking and system resistance tests.

Environmental Factors

Environmental factors such as dirt and humidity can also affect the performance of an ESD floor. When a floor is not properly maintained, the dust and dirt on its surface act as insulators, preventing shoe soles from making proper contact with the ESD floor—in essence, turning it into a regular, non-ESD surface.

Low humidity can decrease the conductivity (increase resistance) of a floor by up to two magnitudes. For a floor measuring within the acceptable resistance range—10E5 – 10E8—humidity generally has little effect on performance. If the resistance of the floor is too high—above 10E8—low RH may increase its resistance to as high as 10E10, turning what appeared to be a compliant ESD floor into a static-generating insulator.

How to Conduct Walking Body Voltage and Electrical Resistance Tests

In these two videos, you’ll learn how to conduct the critical walking body voltage and electrical resistance tests before selecting an ESD Floor.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.