Maintenance Videos

Play Video about Background image is an installation of AmeriWorx ESD solid vinyl tile. In the foreground at the bottom are two boxes. The top is a bright blue with the StaticWorx logo. The second is a dark blue-gray and includes the text in white: “AmeriWorx ESD Vinyl Tile: Post-Installation Maintenance"

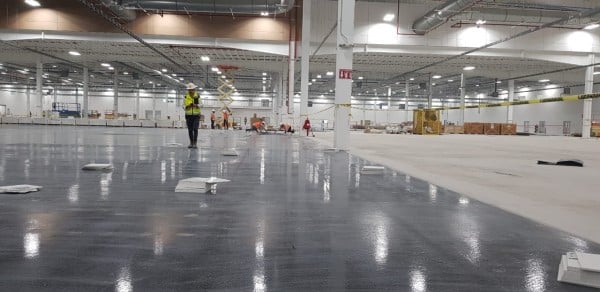

Play Video about Background image is a completed installation of AmeriWorx ESD solid vinyl tile in a large facility. In the foreground at the bottom are two boxes. The top is a bright blue with the StaticWorx logo. The second is a dark blue-gray and includes the text in white: “AmeriWorx ESD Vinyl Tile: Ongoing Maintenance"

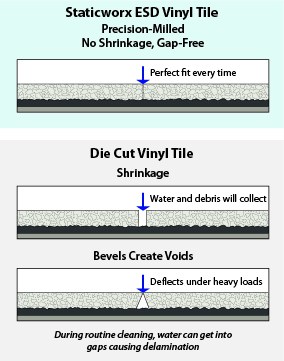

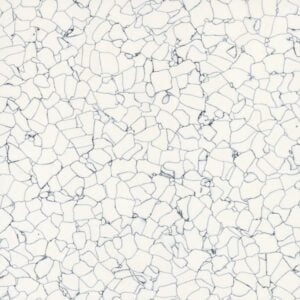

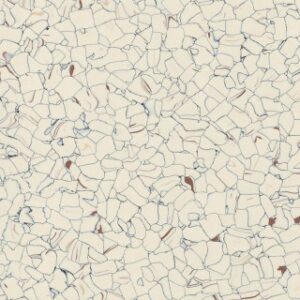

Some low-cost producers die-cut their vinyl tile while still warm, resulting in imprecisely sized—not square—tiles with a tolerance of plus or minus one-tenth of an inch. To slash costs, they forgo secondary processes that would correct excessive tolerances after the tiles have cooled.

Some low-cost producers die-cut their vinyl tile while still warm, resulting in imprecisely sized—not square—tiles with a tolerance of plus or minus one-tenth of an inch. To slash costs, they forgo secondary processes that would correct excessive tolerances after the tiles have cooled.