How Do You Install an ESD Floor?

[12 min read]

ESD Flooring Is Easy To Install

Hire Locally or Consider Using Your In-House Facilities Team

THE GIST: How TO Install an ESD Floor

- You do not need a specialty flooring installer to install ESD flooring. It’s not a black art. It’s easy.

- Before agreeing to a firm price for the installation, ask questions: What is the condition of the subfloor? Is the concrete ready for use? Does the floor have a vapor barrier or need moisture mitigation?

- Always test the subfloor for moisture: vapor problems can cause flooring failure and are not always visible.

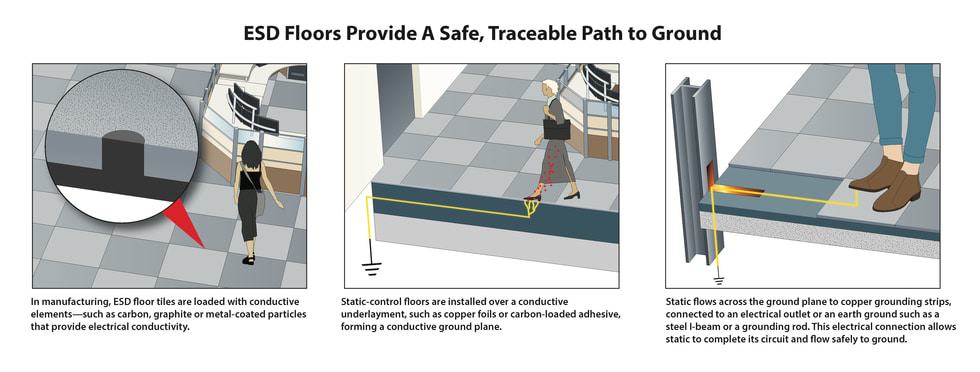

- For full instructions on grounding methods, see our post, How to Ground an ESD Floor

- Avoid installation failures by testing for moisture vapor drive and/or contaminated concrete.

“Other than following simple grounding procedures and using conductive adhesives, there is no difference between installing conventional flooring and static-control flooring.”

As with any construction project, it generally makes sense to hire locally. Local contractors are reliable in part because they’re interested in obtaining all of their customer’s flooring business, not just in a one-shot deal involving a few thousand feet of conductive flooring.

First, every construction project requires multiple types of flooring, to cover areas ranging from cafeterias to bathrooms to lobbies and public spaces.

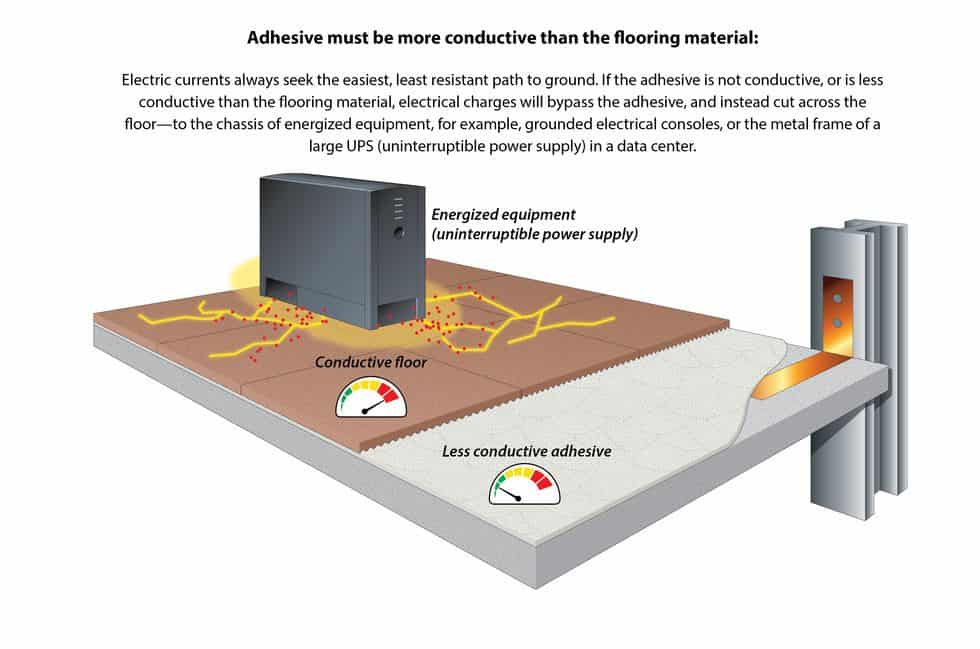

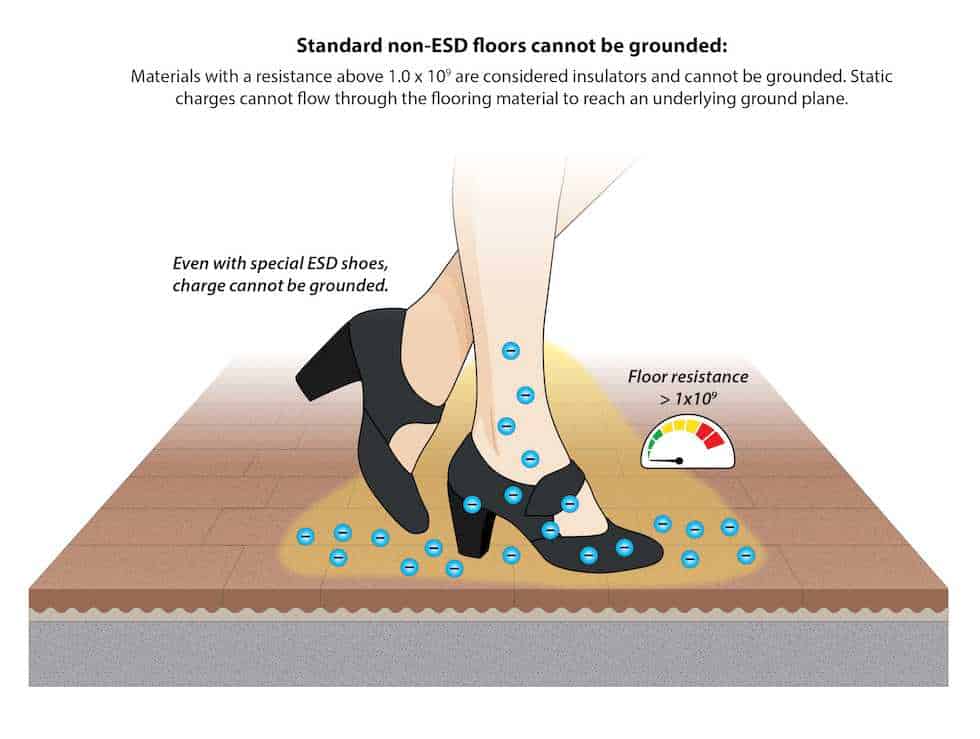

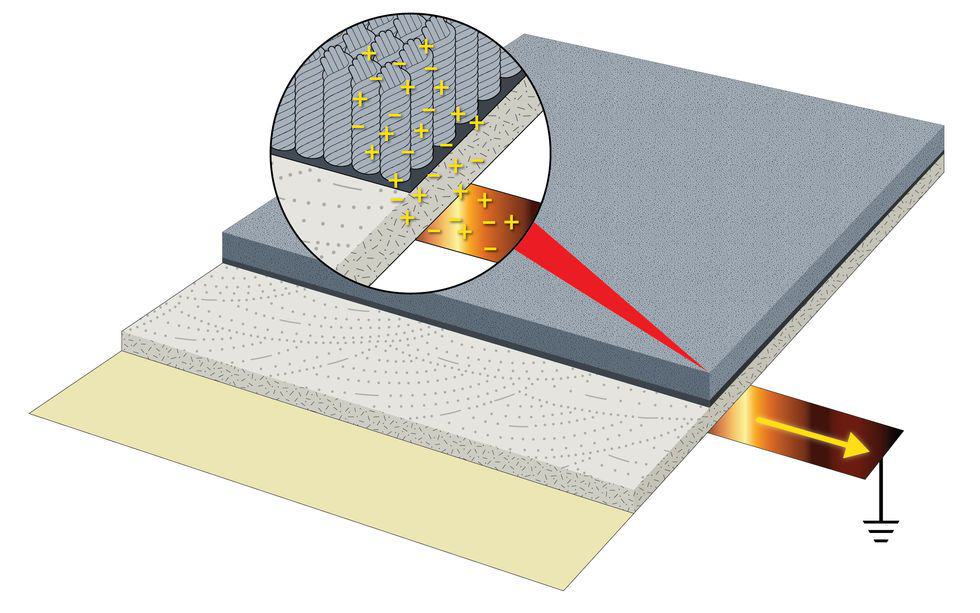

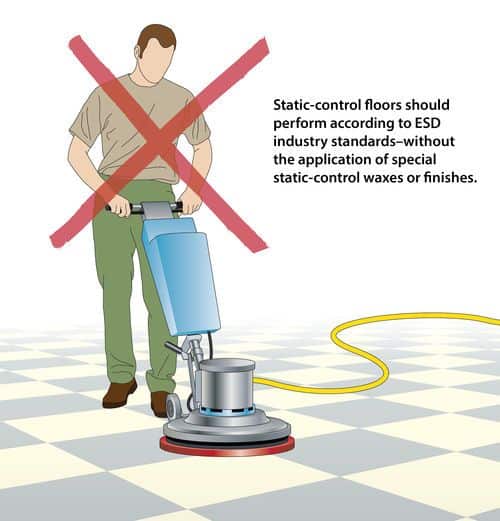

Second, there’s no reason to hire a sub-contractor they don’t know or have never worked with. Other than following simple grounding procedures and using conductive adhesives, there is no difference between installing conventional flooring and static-control flooring.

ESD flooring installation is not some kind of black art. ESD floors are no more difficult to install than ceramic flooring, regular carpet or conventional tile. In many cases, larger electronics companies utilize members of their own in-house facilities department for their static-control flooring installation. Grounding is simple; new carbon-free conductive adhesives are easy to spread; and clean-up is usually done with soap and water.

What Questions Should I Ask Before Installing an ESD Floor (or agreeing to a firm price for installation)?

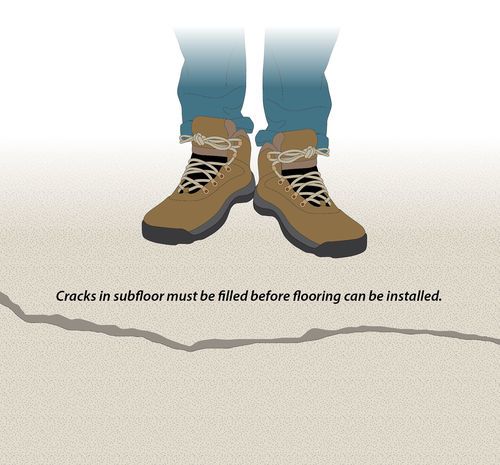

- What is the condition of the subfloor? Will the floor need to be leveled or patched? Are there cracks that need to be filled?

- Is the concrete ready for use? New (green) concrete takes a minimum of 90 days to cure. Because of its high moisture content, adhesives will not adhere to green concrete without installing the proper type of curing compound or base coat.

- Does the floor need a moisture barrier or special moisture-mitigating curing compound? Along with assessing the subfloor, environmental conditions of the building site—conditions under and around the subfloor—should also be evaluated. Moisture varies according to fluctuating environmental conditions, topography and variations in subterranean activities related to water table, drainage, and aquifer.

Moisture problems are not always visible or obvious: Certain dry environments—in places like Colorado, Arizona and California, for example—experience some of the worst vapor problems in North America.

Moisture barriers and mitigation compounds can be expensive. However, installing a moisture barrier after the floor fails will far exceed the costs to have alleviated any moisture problems upfront.

- Is there a vapor barrier? Most floors perform poorly or even fail when laid over a subfloor with vapor problems. As noted above, moisture varies according to fluctuating environmental conditions, topography and variations in subterranean activities related to water table, drainage, and aquifer.

When evaluating flooring costs, the potential need for topical vapor barriers must be taken into account. According to experts in the resilient flooring industry, the moisture levels of a subfloor should be no higher than 75% RH per ASTM 2170 in sutu probe test method. - Perform ASTM F-2170 – Standard Test Method for Determining Relative Humidity in Concrete Floor Slabs Using In-Sutu Probes: This test shows the relative humidity of the concrete slab over time. The maximum relative humidity should be below 75%.

- Perform ASTM-F-1869 – Standard Test Method for Measuring Moisture Vapor Rate of Concrete Subfloor Using Anhydrous Calcium Chloride: The maximum allowed transmission rate is 3 pounds per 1,000 square feet.

- Perform ASTM-D4263 – Plastic Sheet Test: This is a visual test that may provide an indication of the presence of moisture.

DO test and evaluate every sub-floor properly—regardless of previous experience—before flooring is installed, and never ignore defects or marginal moisture vapor readings.

If the building will be purchased or leased, it’s a good idea to perform this testing prior to signing any real estate agreements.