The Need for Due Diligence in Specifying ESD Flooring

[31 min read]

Post Sections

To avoid liability, specifiers must ask what they need to know – as well as what they should have known. Learn what you should know about ESD flooring.

Need additional information about specific ESD products? Learn more about the StaticWorx ESD flooring range.

ESD Sensitivity and Risks for Personal Safety and Electronic Equipment

Specifying building materials of any kind is a challenge, requiring patience, skill, and a general knowledge of the product and its place in the ecosystem. Providing the right specifications for electrostatic discharge (ESD) preventive flooring presents an opportunity for architects and design/construction professionals to help prevent static-induced equipment failures, electronic product returns, critical communication errors, and personal injuries.

As such minute static charges are imperceptible to humans, there’s no way to know a static problem exists, until it’s too late.

Electrostatic discharge (ESD) is the sudden, spontaneous transfer of electric current. In commercial business environments, this sudden discharge can ignite flammable liquids, attract contaminants, disrupt data, cause dropped or lost calls, and damage or destroy the microchips in electronic components—including handheld devices—with losses to business ranging from a relatively inexpensive repair to facility shutdown and lost production time.

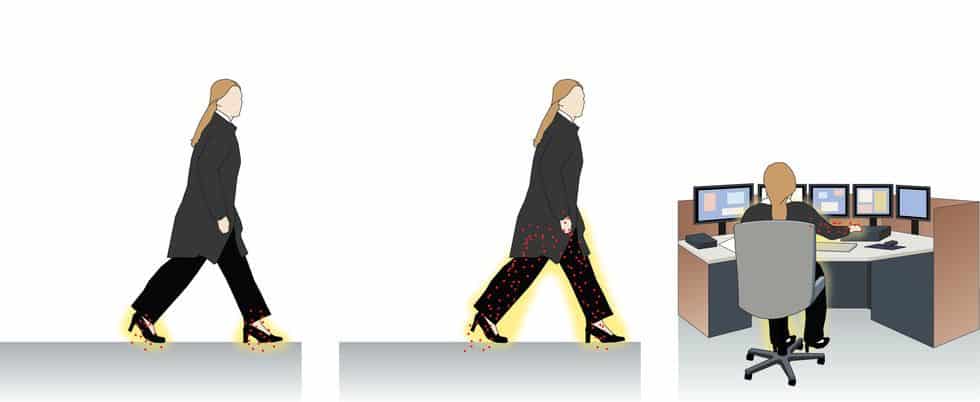

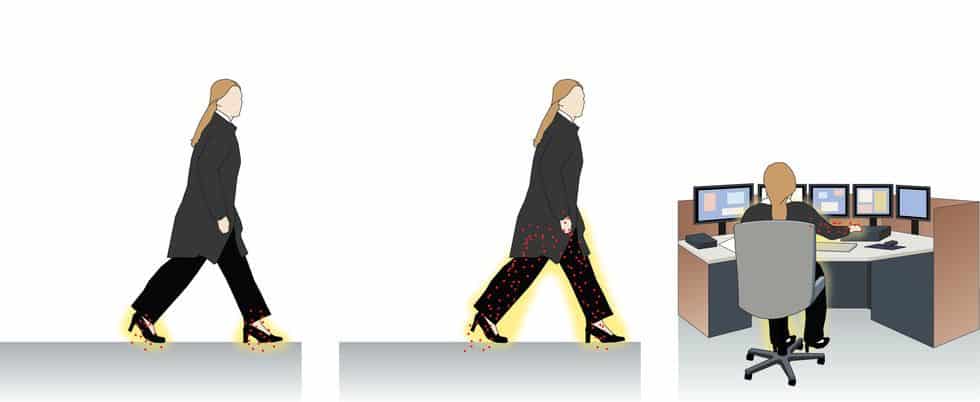

The biggest contributor to ESD in the workplace is static buildup on the human body. When people walk, the friction (or contact and separation) between the soles of their shoes and the floor generates static electricity. Static charges continue to build as they walk, then discharge to the first person or object they touch. Touching another person, a doorknob, or metal parts on a chair results in an irritating, sometimes mildly painful static shock.

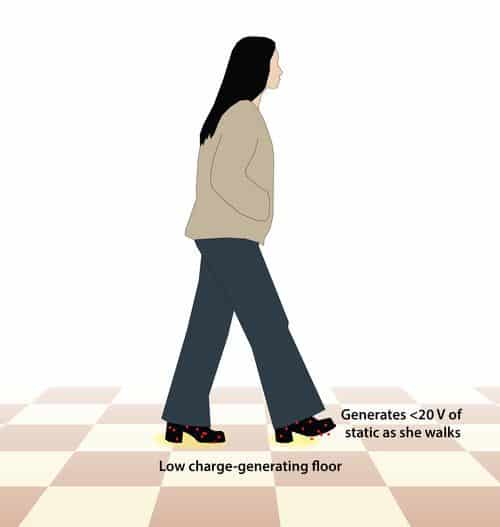

For humans to feel a static shock, the discharge must be at least 3500 volts. Yet a static discharge of only 20 V, far below the human threshold to perceive an electrical shock, can zap telephony equipment, fry circuit boards, destroy the microchips in today’s ultra-fast, ultra-sensitive electronic components, or knock out entire networked computer systems.

Liability: Standard of Care

At home, safeguards such as ground fault interrupters and building code inspections protect against electrical shock and other potentially harmful situations. But what about safeguards in the workplace? The fact is, manufacturers, installers, and specifiers can be held liable for any damage or harm their products might cause.

In an article published by In Compliance Magazine in January 2012, nationally known liability attorney Kenneth Ross states, “Industry standards and even certifications like UL are considered minimum. As a result, compliance with standards and certifications is not an absolute defense, although it is pretty good evidence that the product was reasonably safe. Therefore, as with laws and regulations, the plaintiff can argue that you should have exceeded the standards. However, noncompliance is a problem if it caused or contributed to the injury. The reason is that the standard establishes a reasonable alternative design and the manufacturer has to justify why it didn’t comply.”

In the case of ESD flooring, reasonable alternatives to unsafe or non-performing static-control floors certainly exist. In looking for the best solution, as noted above, it is prudent to exceed safety and electrical thresholds and never specify a lower electrical resistance than standards and compliance documents recommend. To ensure electrical performance, it’s crucial to understand ESD terminology, industry standards and test methods, and to evaluate the environmental conditions and the use (or lack of) static-protective footwear.

Protecting equipment from ESD requires specialized fault-tolerant static-protective flooring. In fact, facility managers in environments as diverse as semiconductor manufacturing, flight control operations, and casino command centers view static-free flooring as the most effective way to mitigate ESD problems, because it prevents static generation in the first place.

With a broad range of materials to consider, from inexpensive low-quality paints and waxes to high-end floors like ESD rubber; electrical parameters that vary by application and footwear; environmental conditions such as moisture, RH, and subterranean vapor to factor into the equation; never mind technical issues, such as ensuring that the floor passes electrical resistance tests and is a low static-generating material—specifying the right ESD floor can be daunting.

Naturally, specifiers want to—and should—provide clients with flooring solutions that best meet their needs. In an increasingly litigious society, specifiers must also protect themselves against the costly litigation that can arise if a product fails—sometimes months or years down the road—or when client expectations, however unreasonable, are unmet.

Even if complaints are resolved without legal action, the tangible and intangible costs of an errors and omissions (E&O) accusation add up—in broken relationships, uninsurable losses, and unpaid invoices, never mind countless non-billable hours spent analyzing and fixing the problem.

To protect themselves against losses, it’s not enough for specifiers to ask, “What are the basics I need to know?” Specifiers must also ask, “What else should I have known?”

✓ visual selector guide;

✓ walking body voltage/low static generation;

✓ resistance requirements and testing;

✓ ESD flooring comparison;

✓ industry standards & test methods;

✓ key ESD terms

Need for Due Diligence

To limit exposure, ideally specifiers should ensure that the flooring they select protects worksites on three levels: personal safety, environmental health, and static protection. To ensure personal/personnel safety, the floor should meet all applicable safety standards. Slip resistance, for instance, can help prevent slips and falls which, according to OSHA, account for 25% of claims per year and over 17% of all disabling injuries.*

* OSHA, “Slips, Trips, and Falls: Identification and Prevention”

Electrical Resistance: Preventing Shocks

Ensuring that an ESD floor meets standards for electrical resistance can prevent the risk of electrical shocks. Resistance standards differ by industry. ANSI/ESD S20.20, the standard for the electronics manufacturing and handling industry, does not define a minimal electrical resistance. S20.20 does, however, require the use of ESD footwear—toe, heel or sole straps or ESD shoes. The built-in resistors in ESD footwear provide the wearer with some protection against electrical shocks, negating the need to define a value for minimum electrical resistance.

Most standards for end-user environments—e.g., critical-call centers, 9-1-1 dispatch operations, flight towers, networked government offices, university labs, and other end-user spaces—set a minimum resistance value of 1.0 x 10E6 ohms. This protects workers from shocks in areas where energized equipment is in use. More on electrical resistance below.

Other Considerations

Outgassing, hazardous chemicals, acoustics and other environmental considerations must also be taken into account. Our focus in this post is primarily on ESD protection and how to ensure that the floor meets the client’s needs and expectations.

Static Protection: Understanding the Terminology

Installing the right ESD floor for the application eliminates the source of static problems. Unfortunately, many specifiers, unfamiliar with static-control terminology, standards, protocols, or technical details, choose flooring that’s wrong for the application or fails to meet industry standards. Part of the problem is a disconnect among architects, contractors, flooring distributors, manufacturers, and end users.

Flooring manufacturers and distributors know flooring, and ESD specialists know about static prevention, but neither communicates much with the other. This puts specifiers in a bind, because the information they receive from flooring professionals is often inconsistent with that from static-control providers. Even with the best of intentions, specifiers may choose the wrong floor, because they don’t know where to turn or whom to believe.

ESD terminology is particularly confusing because a word’s common usage sometimes differs from its technical meaning. For example, many ESD terms have specific quantitative ANSI and ASTM definitions*. You can’t know the esoteric details of a specialized technology industry from the outside. It’s easy to get tripped up by the generic descriptions of products that may sound ideal, when in fact they are totally the wrong choice.

Some static-dissipative vinyl materials, are marketed as an “anti-static flooring solution,” for example. The term antistatic is misleading because, in fact, ESD vinyl—whether dissipative or conductive—is a static-generating material (generates charges, called walking body voltage, on people as they walk across the floor).

Furthermore, to meet the needs of most applications, static-dissipative vinyl must be polished with three to five coats of a special anti-static wax. You would not pick up on this idiosyncrasy from reading a technical sheet. In all likelihood, no one would discover that antistatic wax was tied to performance-until the floor failed post-installation electrical tests, and the end user found a few pails of a special wax, left behind with no explanation from the flooring installer.

Dissipative is a good example of a term that often causes confusion. Static-protective floors transport—or dissipate—electrical charges to ground. Here, we’re using the word dissipate in its dictionary sense—i.e., of making static disappear. With ESD flooring, both static-dissipative and conductive materials will discharge—or dissipate—static to ground.

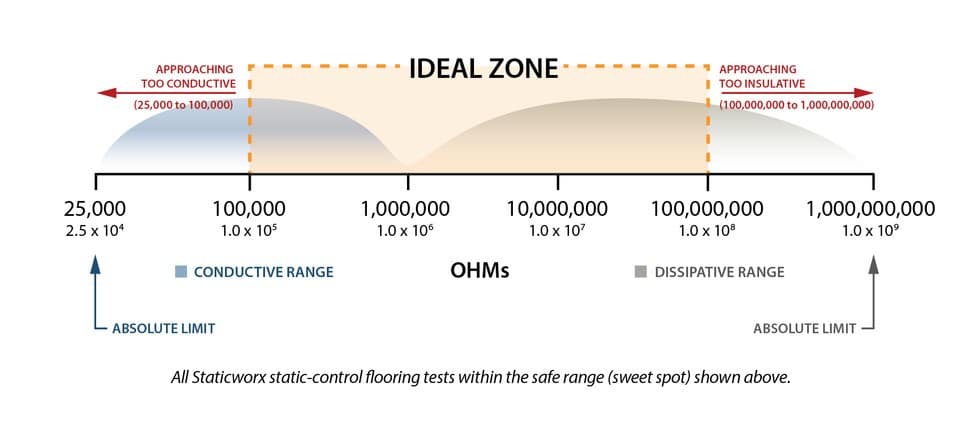

In terms of industry standards and tests, static dissipative refers to materials with a very specific electrical resistance: measuring between 1 x 10E6 and 1 x 10E9 ohms. Measurements below 10E6 are conductive, and measurements above 10E9 are insulative. For safety and performance, static-dissipative materials measuring between 10E6 and 10E8 are generally considered to be within the optimal resistance range.

However, conductive rubber outperforms dissipative rubber and offers permanent ESD protection. With the exception of carpet, which poses a safety risk if it’s too conductive, there’s no hard and fast rule to say a material “should be” conductive or “should be” static dissipative.

To further complicate matters, research shows that static-dissipative floors measuring above 10E8—even though they meet the ANSI/ESD standard—discharge static too slowly to effectively eliminate the risk of random ESD events. So a floor that meets the generic specification “static-dissipative,” could fail to protect against static.

ESD Specs: Generic Resistance Terms Are Problematic

Another problem is that specifications for ESD flooring are often based solely on a generic resistance range*-that is, the spec requires that the floor be “conductive” or “static-dissipative.”

This is a problem for three reasons. First, the terms are too broad. The ANSI/ESD S20.20 standard for the electronics industry approves for use any material measuring below 10E9 ohms. Research has shown that floors measuring above 10E8—in the static-dissipative range—may drain charges too slowly to adequately protect against random static discharge.*

If a floor is specified only as “static-dissipative,” the specification allows the selection of an effective material—i.e., from 10E6 to 10E8—as well as an ineffective one, measuring above 10E8. This means the client could end up with a floor that meets the spec, but does not prevent ESD problems.

At the other end of the spectrum, a floor that is too conductive could pose a safety hazard. Under standard of care, specifiers are responsible for weeding out products that could expose personnel to an unsafe situation.

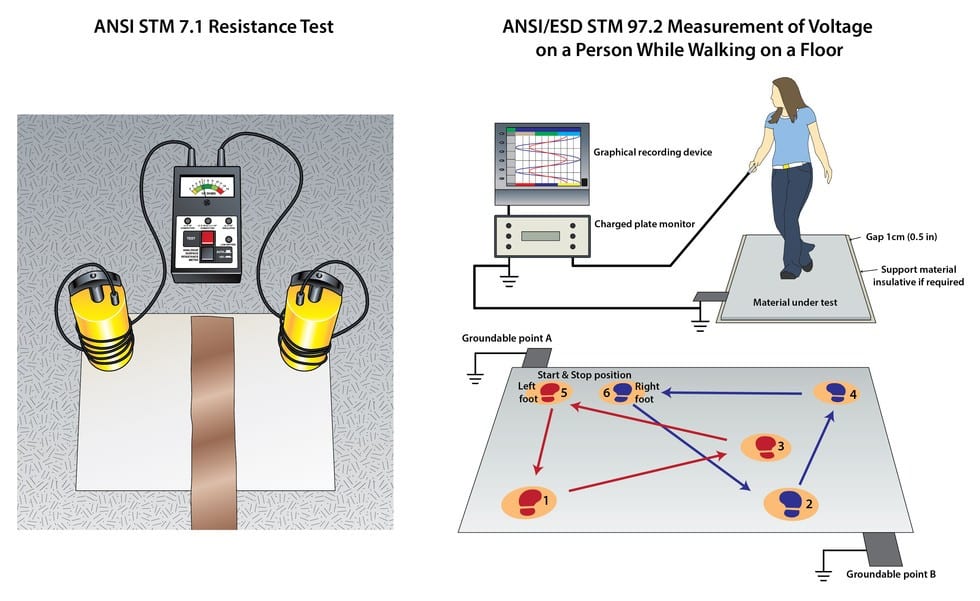

- Resistance tests, which measure how quickly or slowly currents flow across or through a material, are used to evaluate the conductivity of ESD flooring.

Optimal Conductivity Varies by Material

Second, optimal conductivity varies, depending upon the manufacturing process and chemical makeup of the material. Conductive rubber, for instance, with carbon veins embedded in the manufacturing process, outperforms static-dissipative rubber, which tends to lose its dissipative properties over time.

With carpet, static-dissipative materials—with a resistance measuring 1.0 x 10E6 – 1.0 x 10E8—discharge static as effectively as conductive carpet, without posing the potential safety risk.

Generic resistance terms fail to account for static generation

Third, specifications based solely on a resistance range neglect to account for static generation. A floor can have optimal resistance readings and still generate enough static to disrupt or destroy data and damage the microcircuits inside high-speed electronic equipment.

How ESD Flooring Works

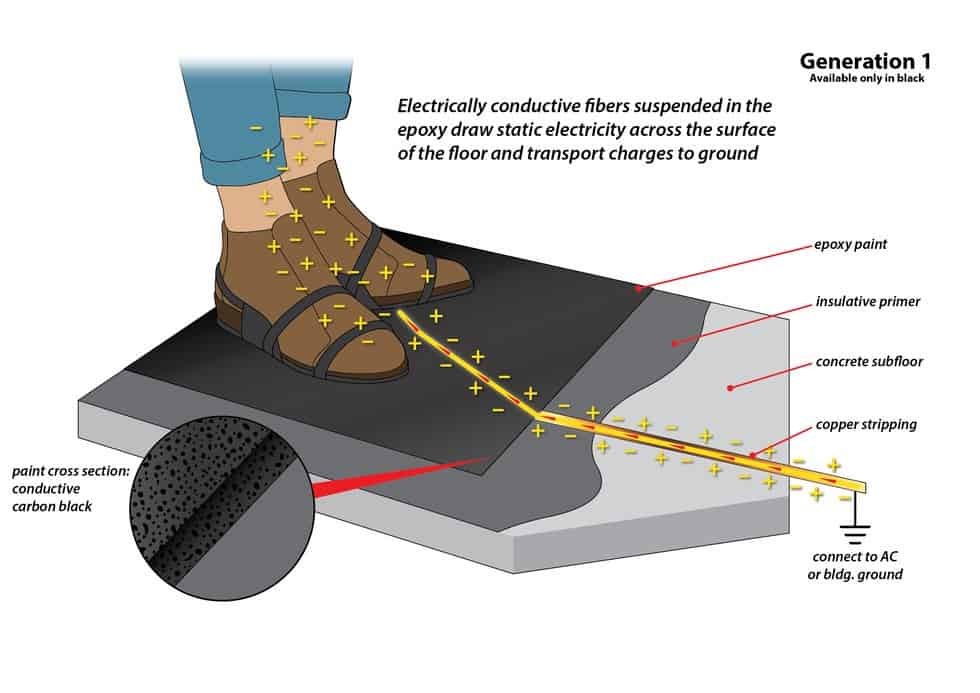

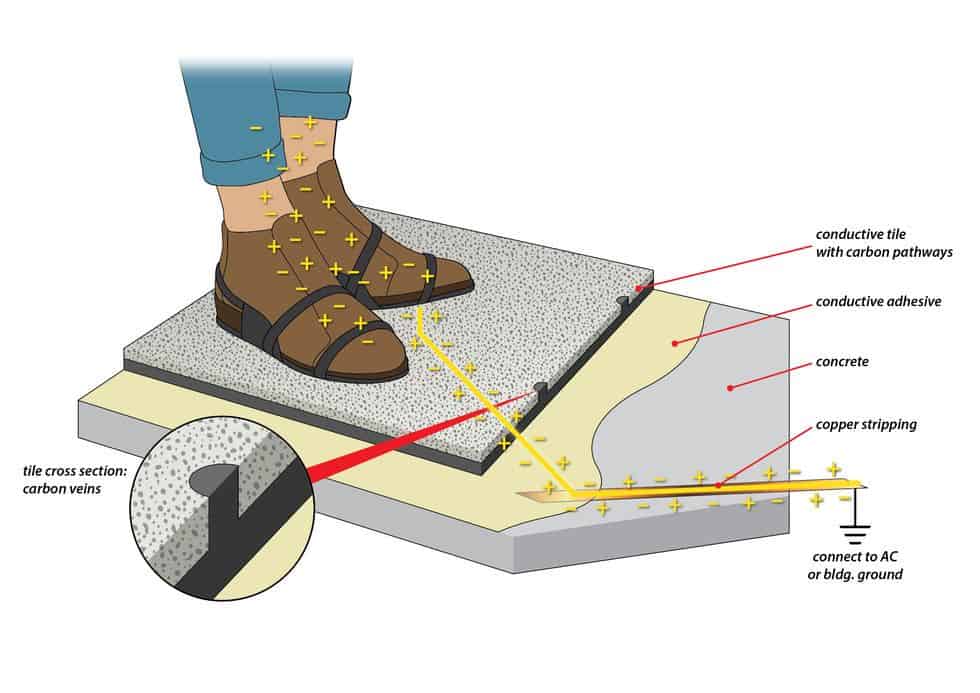

The right ESD floor should withstand punishment in high-traffic areas without fracturing or losing conductivity. In an effective ESD floor with permanent conductivity, conductive fibers, particles or additives are introduced into the flooring material during the manufacturing process. These conductive additives link the surface of the floor to a conductive adhesive or other type of conductive underlayment, drawing static charges away from people at a safe and controlled rate of dissipation.

The conductive adhesive or underlayment forms a ground plane under the walking surface, with charges flowing across the ground plane to a steel I-beam or other form of earth ground.

ESD Flooring Types

- Overview

- ESD Rubber

- ESD Carpet

- ESD Vinyl

- ESD Epoxy

Before recommending any flooring solution, it’s important to study the environment, taking into account any special ESD concerns, including variables such as type of footwear, traffic, potential maintenance issues, humidity, and any other environmental factors. In some projects, one particular product will solve the problem best. For a budget-conscious electronics manufacturer, with strict protocols in place mandating the use of ESD-protective footwear, for instance, a low-cost conductive vinyl might be the ideal choice.

For other clients, a combination of materials might be a better solution. University labs and R&D facilities often choose ESD rubber, partly because rubber is attractive, durable, and easy to maintain, and partly because it generates very little static electricity—i.e., rubber is a naturally low static-generating material, meaning static won’t build on people as they walk across the floor—whether they wear ESD-protective footwear or regular street shoes. A coordinating static-dissipative carpet in an adjacent engineering office or conference room could put a rich, integrated spin on the overall appearance.

Independent research and lab testing found electrically conductive (EC) rubber flooring as providing the most effective static protection for any application. EC rubber is the only fault-tolerant flooring suitable for Class-0 applications (a working definition of Class 0 is any component that fails under 200 V for the Human Body Model or Charged Device Model). Because it’s a low static-generating material, EC rubber is also the only static-control flooring that works in electronics manufacturing and handling areas, as well as other applications requiring body voltage under 250 V, regardless of footwear.

The selected rubber should be conductive—not static-dissipative. In a 7-year study by Lucent Technologies, the conductivity of static-dissipative rubber was shown to deteriorate over time; at 7 years, SD rubber had lost its ESD-protective properties and its ability to meet current ANSI/ESD standards.

EC rubber meets all domestic and international industry standards as well as recommended test parameters from the following documents:

- American National Standards Institute/Electrostatic Discharge Association (ANSI/ESD) S20.20, Protection of Electrical and Electronic Parts, Assemblies, and Equipment (Excluding Electrically Initiated Explosive Devices);3

- IEC61340-5-1 International standard: Protection of electronic devices from electrostatic phenomena – General requirements

- ANSI/ESD STM97.1, Floor Materials and Footwear: Resistance Measurement in Combination with a Person;

- ANSI/ESD STM97.2, Floor Materials and Footwear: Voltage Measurement in Combination with a Person;

- S. Department of Defense (DOD) 4145.26-M, DOD Contractors’ Safety Manual for Ammunition and Explosives; and

- National Aeronautics and Space Administration (NASA)-grade cleanroom requirements.

- EC rubber also meets all criteria in the now-defunct standard for conductive flooring set by the National Fire Protection Agency (NFPA) 99, Healthcare Facilities.

EC rubber also complies with CDPH Standard Method V1.2, widely known as CA Section 01350.

EC rubber is free of halogens, polyvinyl chloride (PVC), lead, phthalates, and asbestos.

EC rubber is a durable material, designed to last forever. Rubber tiles and sheet flooring can withstand high traffic and heavy loads. Ergonomically, rubber is a better anti-fatigue floor than either epoxy or vinyl, and, like carpet, dampens noise. As rubber is less porous than vinyl, it is also easier to clean, wash, and maintain, and never needs conductive wax.

EC rubber has been identified in an ASHRAE study as the lowest static-generating floor for data centers, making it ideal for end-user applications, such as call center operations, computer labs, R&D labs, hospitals, and other 24/7 mission-critical environments with zero tolerance for static. In Class-0 ESD environments, when combined with controlled footwear, EC rubber eliminates the need for wrist straps on mobile personnel.

Though its installed cost is the highest among the various options, because it’s durable and inexpensive to maintain, the total cost of ownership for rubber is relatively low.

Risk Factors

Though a durable, hard-surface material, rubber has more give than vinyl or epoxy surfaces. and can be damaged, in areas like shipping and receiving, from activities such as dragging pallets with exposed nails. Rubber floors also require a good installer.

Pros

- Attractive

- Durable

- Ergonomically sound—anti-fatigue and slip-resistant; attenuates sound

- Free of halogens, polyvinyl chloride (PVC), lead, phthalates, and asbestos

- Glue-free options do not require conductive adhesive

- Easy to maintain

- Low Total Cost of Ownership (including material, installation, and maintenance costs)

- Low Charge Generating

- Only ESD flooring material that inhibits static regardless of footwear

- Only fault-tolerant flooring suitable for Class-0 applications

- Meets all industry standards for ESD flooring

Cons

- Highest installed cost of ESD flooring options

- Not the best choice for shipping and receiving environments

ESD carpet has come a long way since the days of the so-called “low kV” or “computer-grade” carpeting, designed to protect people from static shocks. While low kV carpet is fine for residential environments, it cannot be grounded, and does not offer anywhere close to the static-protective properties necessary to protect sensitive electronic components.

In static-dissipative carpet, conductive fibers can be introduced into the yarn bundle early in the process, creating an almost infinite number of electrical contact points, providing a fast and reliable path to ground. ESD carpet—when constructed with fibers that have an extremely low modification ratio—is robust and capable of providing many years of static protection in severe environments, such as electronics assembly, 9-1-1 call centers, and high-traffic mission-critical spaces.

Tiles with random non-directional designs hide imperfections and can be replaced, as needed, without affecting the overall appearance of the installation, extending the life of the floor.

Carpet tiles can be installed with clean, fast-drying release adhesives or with a free-floating interlocking method called Staticworx GroundbridgeTM.

Carpet tile can be placed directly over old epoxy, access floors, vinyl tile or uneven concrete, lowering installation costs. If the carpet is accidentally damaged, the area can be easily replaced without special tools by simply lifting the damaged tile and setting a new tile in its place, laying it directly into the old adhesive or GroundBridge installation.

Risk Factors

Like any material, carpet has disadvantages. It cannot accommodate regular traffic from heavy loads such as forklifts and pallet jacks; on carpet, it’s also difficult to roll heavy carts (> 500 pounds) or systems on small wheels. Carpeting has low resistance to chemicals and solvents, and, with its multi-colored, textured surface, small electronic parts, if dropped, could be hard to find.

The biggest challenge lies in finding carpet with permanent static-control performance that also meets the safety requirements for flooring used around operational computers and electrical equipment. Some carpet tiles, often generically described as “conductive-level carpet,” are too conductive for use in public spaces, or environments like call centers, emergency dispatcher operations, schools and server rooms.

Telecommunication-facility grounding standards and FAA standards for flight-control towers** expressly forbid the use of highly conductive floors in areas where people work with energized equipment. Specifiers can avoid liability by requiring electrical resistance between any two points (RTT) on the floor to measure at least 1 x 10E6 (1 million ohms) or above.

* The built-in resistor in ESD footwear slows the rate of static dissipation and protects the wearer from most electrical shocks.

** Standards include: Alliance for Telecommunications Industry Solutions ATIS-0600321, Electrical Protection for Network Operator-type Equipment Positions, Motorola R56, and FAA 019f.

- Attractive

- Moderately priced

- Yarns with low modification ratios can withstand heavy traffic

- Anti-fatigue and slip resistant

- Designs with random patterns provide longevity

- Easy to install and replace

- Can be installed over old floors

- Does not require conductive adhesive

- Easy and inexpensive to maintain

- Carpet measuring between 1.0 x 10E6 and 1.0 x 10E8 meets all industry standards

Cons

- Cannot withstand heavy loads or rolling carts

- Should not be installed in areas where solder and solvents are used

- Some designs can camouflage small tools or other items that fall on the floor

- Some conductive carpet does not meet resistance standards for end-user environments

When people walk across the floor, the carbon veins in a conductive SVT form an electrical bond between the floor and shoe soles, drawing static away from the human body to ground. To evaluate the conductivity of a floor, or its ability to transport charges to ground, we perform an electrical resistance test. Conductive vinyl easily measures under 1.0 x 10E9 ohms, the ANSI/ESD maximum acceptable measurement for electrical resistance, and usually tests in what we call the “Sweet Spot,” between 1.0 x 10E5 and 1.0 x 10E8, the ideal resistance range.

Note: ESD vinyl (dissipative or conductive) is a static-generating material. Vinyl does not inhibit static when people walk on the floor with regular static generating footwear. ESD vinyl meets ESD standards for charge generation only if every person in the space wears special ESD-protective footwear.

Unlike less expensive static-dissipative vinyl composition tiles (VCTs), SVT controls static without the need for periodic ESD-wax or polish treatments. Most manufacturers recommend cleaning methods that steer clear of finishes, polishes, or waxes. Since SVT is uniform throughout the thickness of the tile, high-speed buffing—what maintenance professionals call “burnishing”—is sometimes recommended for cleaning.

Over time, burnishing can damage the tile, making simple washing and low-speed buffing the preferred cleaning method.

Using conductive dry adhesives or fast-drying pressure-sensitive adhesives, low in volatile organic compounds (VOCs), some ESD vinyl can be installed in occupied spaces, right over the old floor, eliminating the need for shutdown during installation. For installers, leaving the floor in place reduces exposure to pre-existing dangerous contaminants like asbestos in older VCT tiles.

Risk Factors

To avoid unsightly installations, with gaps between seams, be sure the vinyl tiles will not shrink from plasticizer migration. Before selecting any vinyl tile, specifiers should ask:

- Where are the tiles manufactured?

- Is the material free of heavy metals, dioctyl phthalate (DOP), and bis(2-ethylhexyl)phthalate (DEHP) plasticizers?

- Does it meet all specifications for squareness and standards for electrical properties?

Must Be Used in Conjunction with Static-Protective Footwear

Once static builds on the body, the most conductive flooring material cannot bleed the charge quickly enough to prevent static from discharging when the person touches an electronic device—in other words, cannot protect electronics from the threat of random ESD events.

The conductive material in static-protective footwear—heel straps, toe straps, or special ESD shoes—forms an electrical bond between the wearer and the floor, preventing static buildup as the person walks across an ESD floor. With the use of protective footwear—and only in conjunction with special ESD footwear—conductive vinyl meets industry standards.

Without ESD-protective footwear, conductive vinyl is a static-generation liability.

As the floor cannot prevent static generation without ESD footwear, it’s suitable for use only in areas where special static-protective footwear is mandated and mandates are strictly enforced—generally true of most electronics manufacturing facilities. ESD vinyl is not suitable for use in 24/7 mission-critical call centers, dispatch centers, flight towers, or any other space in which people wear regular, non-ESD street shoes.

- Attractive

- Mono-lithic design creates clean, hospital-like appearance

- Moderate cost

- Durable

- Can handle high traffic and heavy loads

- Easy to install and repair

- Some ESD vinyl can be installed over old floors

- Snap-together options can be installed over subfloors with moisture problems

- In conjunction with ESD footwear, meets industry standards for electronics manufacturing and handling environments

Cons

- Static-dissipative (SDT) vinyl gains ESD properties from special wax or polishes

- Static-generating material: can only be used in conjunction with ESD footwear

- Unsuitable for use in 24/7 mission-critical or other end-user environments

In areas constantly exposed to heavy loads and high traffic, epoxy can be a very practical flooring choice.

Risk Factors

While epoxy coatings are ruggedly hard, the shiny slickness of the floor poses a slip and fall risk, and sounds tend to bounce off the hard surface and echo throughout the facility.

Epoxy is also easily scratched and difficult to repair.

Another downside: due to the high potential for field errors—improper mixing, spread-out, or unanticipated traffic during or immediately after the installation, for example—it is impossible to tell what an epoxy floor will look like or how well it will meet ESD electrical parameters until after it has been installed and fully cured.

Different Types of Epoxy

Inexpensive, first generation epoxies consist essentially of a black, carbon-loaded paint, creating a durable, no-frills, static-control surface.

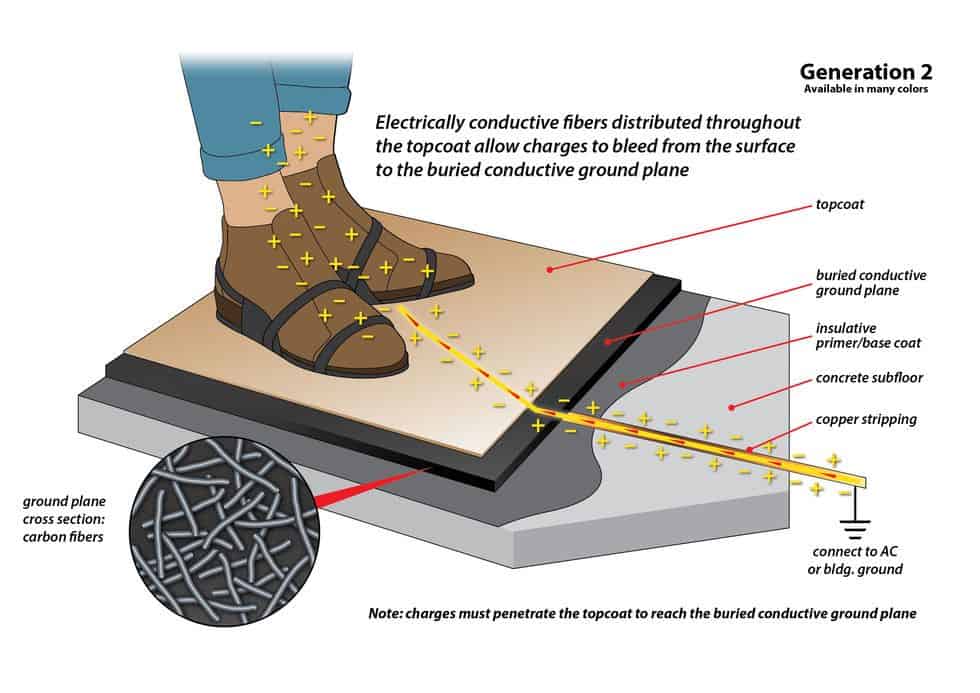

Second-generation epoxies layer a colorized semi-conductive topcoat over a buried black primer (with embedded carbon) as part of the overall thickness of the coating, providing redundant paths to ground.

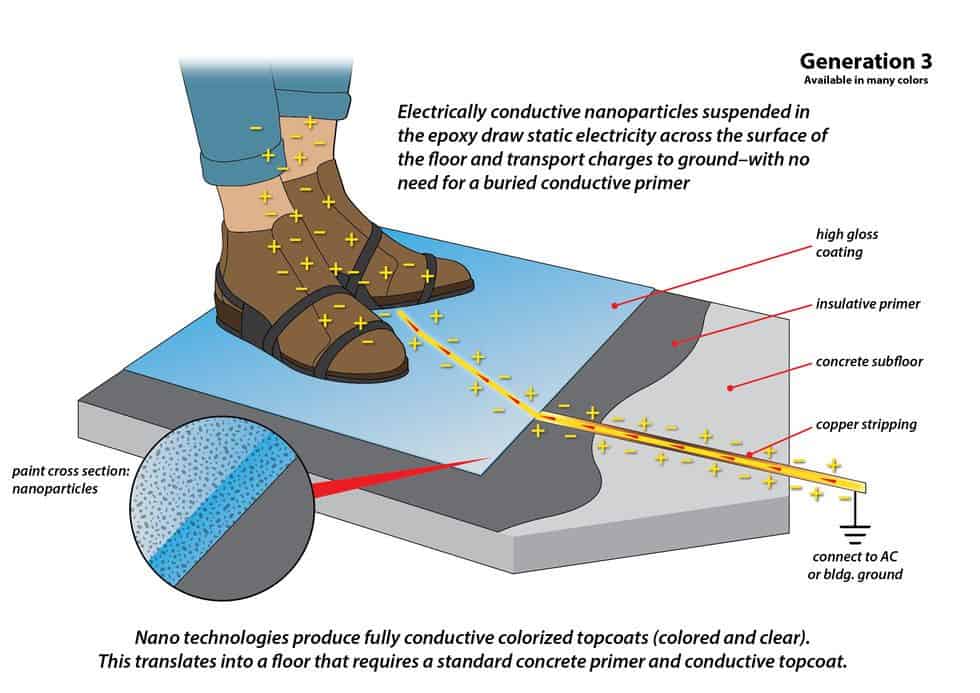

Newer technologies embed transparent conductive nanoparticles into a high-gloss topcoat, without the need for a conductive buried black primer—allowing for easy application, a wide array of colors, and superior static protection.

Epoxy May Not Meet ESD Standards

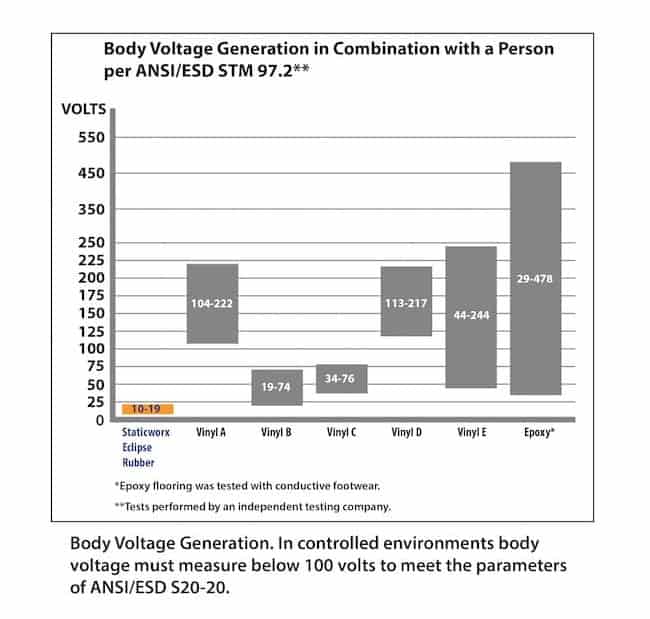

Properly installed, epoxies meet most ESD resistance standards. Unfortunately, most formulations of ESD epoxy coatings do not meet the new walking body voltage testing requirements per the ANSI/ESD S97.2 test method.

ESD epoxy will not prevent static without the rigid use of special static-preventive footwear. If people using the space wear normal street shoes, static-control epoxy floors will generate almost the same amount of static as their non-static-control counterparts.

- High gloss finish

- Seamless

- Durable

- Rugged

- Low cost

- Withstands high traffic and extremely heavy loads, including pallet jacks

- Used with ESD footwear, most high-quality epoxy products meet industry standards

Cons

- Poor ergonomics

- Slip and fall risk

- Sounds echo

- Easily scratched

- High potential for field errors during installation

- Difficult to repair—area under repair must be evacuated for several days

- Can be used only in conjunction with ESD footwear

- Unsuitable for use in 24/7 mission-critical or other end-user environments

- Many ESD epoxy coatings fail to meet walking body voltage requirements

Before recommending any flooring solution, it’s important to study the environment, taking into account any special ESD concerns, including variables such as type of footwear, traffic, potential maintenance issues, humidity, and any other environmental factors. In some projects, one particular product will solve the problem best. For a budget-conscious electronics manufacturer, with strict protocols in place mandating the use of ESD-protective footwear, for instance, a low-cost conductive vinyl might be the ideal choice.

For other clients, a combination of materials might be a better solution. University labs and R&D facilities often choose ESD rubber, partly because rubber is attractive, durable, and easy to maintain, and partly because it generates very little static electricity—i.e., rubber is a naturally low static-generating material, meaning static won’t build on people as they walk across the floor—whether they wear ESD-protective footwear or regular street shoes. A coordinating static-dissipative carpet in an adjacent engineering office or conference room could put a rich, integrated spin on the overall appearance.

Independent research and lab testing found electrically conductive (EC) rubber flooring as providing the most effective static protection for any application. EC rubber is the only fault-tolerant flooring suitable for Class-0 applications (a working definition of Class 0 is any component that fails under 200 V for the Human Body Model or Charged Device Model). Because it’s a low static-generating material, EC rubber is also the only static-control flooring that works in electronics manufacturing and handling areas, as well as other applications requiring body voltage under 250 V, regardless of footwear.

The selected rubber should be conductive—not static-dissipative. In a 7-year study by Lucent Technologies, the conductivity of static-dissipative rubber was shown to deteriorate over time; at 7 years, SD rubber had lost its ESD-protective properties and its ability to meet current ANSI/ESD standards.

EC rubber meets all domestic and international industry standards as well as recommended test parameters from the following documents:

- American National Standards Institute/Electrostatic Discharge Association (ANSI/ESD) S20.20-2014, Protection of Electrical and Electronic Parts, Assemblies, and Equipment (Excluding Electrically Initiated Explosive Devices);3

- IEC61340-5-1-2016 International standard: Protection of electronic devices from electrostatic phenomena – General requirements

- ANSI/ESD STM97.1-2015, Floor Materials and Footwear: Resistance Measurement in Combination with a Person;

- ANSI/ESD STM97.2-2016, Floor Materials and Footwear: Voltage Measurement in Combination with a Person;

- S. Department of Defense (DOD) 4145.26-M, DOD Contractors’ Safety Manual for Ammunition and Explosives; and

- National Aeronautics and Space Administration (NASA)-grade cleanroom requirements.

- EC rubber also meets all criteria in the now-defunct standard for conductive flooring set by the National Fire Protection Agency (NFPA) 99, Healthcare Facilities.

EC rubber also complies with CDPH Standard Method V1.2, widely known as CA Section 01350.

EC rubber is free of halogens, polyvinyl chloride (PVC), lead, phthalates, and asbestos.

EC rubber is a durable material, designed to last forever. Rubber tiles and sheet flooring can withstand high traffic and heavy loads. Ergonomically, rubber is a better anti-fatigue floor than either epoxy or vinyl, and, like carpet, dampens noise. As rubber is less porous than vinyl, it is also easier to clean, wash, and maintain, and never needs conductive wax.

EC rubber has been identified in an ASHRAE study as the lowest static-generating floor for data centers, making it ideal for end-user applications, such as call center operations, computer labs, R&D labs, hospitals, and other 24/7 mission-critical environments with zero tolerance for static. In Class-0 ESD environments, when combined with controlled footwear, EC rubber eliminates the need for wrist straps on mobile personnel.

Though its installed cost is the highest among the various options, because it’s durable and inexpensive to maintain, the total cost of ownership for rubber is relatively low.

Risk Factors

Though a durable, hard-surface material, rubber has more give than vinyl or epoxy surfaces. and can be damaged, in areas like shipping and receiving, from activities such as dragging pallets with exposed nails. Rubber floors also require a good installer.

Pros

- Attractive

- Durable

- Ergonomically sound—anti-fatigue and slip-resistant; attenuates sound

- Free of halogens, polyvinyl chloride (PVC), lead, phthalates, and asbestos

- Glue-free options do not require conductive adhesive

- Easy to maintain

- Low Total Cost of Ownership (including material, installation, and maintenance costs)

- Low Charge Generating

- Only ESD flooring material that inhibits static regardless of footwear

- Only fault-tolerant flooring suitable for Class-0 applications

- Meets all industry standards for ESD flooring

Cons

- Highest installed cost of ESD flooring options

- Not the best choice for shipping and receiving environments

ESD carpet has come a long way since the days of the so-called “low kV” or “computer-grade” carpeting, designed to protect people from static shocks. While low kV carpet is fine for residential environments, it cannot be grounded, and does not offer anywhere close to the static-protective properties necessary to protect sensitive electronic components.

In static-dissipative carpet, conductive fibers can be introduced into the yarn bundle early in the process, creating an almost infinite number of electrical contact points, providing a fast and reliable path to ground. ESD carpet—when constructed with fibers that have an extremely low modification ratio—is robust and capable of providing many years of static protection in severe environments, such as electronics assembly, 9-1-1 call centers, and high-traffic mission-critical spaces.

Tiles with random non-directional designs hide imperfections and can be replaced, as needed, without affecting the overall appearance of the installation, extending the life of the floor.

Carpet tiles can be installed with clean, fast-drying release adhesives or with a free-floating interlocking method called Staticworx GroundbridgeTM.

Carpet tile can be placed directly over old epoxy, access floors, vinyl tile or uneven concrete, lowering installation costs. If the carpet is accidentally damaged, the area can be easily replaced without special tools by simply lifting the damaged tile and setting a new tile in its place, laying it directly into the old adhesive or GroundBridge installation.

Risk Factors

Like any material, carpet has disadvantages. It cannot accommodate regular traffic from heavy loads such as forklifts and pallet jacks; on carpet, it’s also difficult to roll heavy carts (> 500 pounds) or systems on small wheels. Carpeting has low resistance to chemicals and solvents, and, with its multi-colored, textured surface, small electronic parts, if dropped, could be hard to find.

The biggest challenge lies in finding carpet with permanent static-control performance that also meets the safety requirements for flooring used around operational computers and electrical equipment. Some carpet tiles, often generically described as “conductive-level carpet,” are too conductive for use in public spaces, or environments like call centers, emergency dispatcher operations, schools and server rooms.

Telecommunication-facility grounding standards and FAA standards for flight-control towers** expressly forbid the use of highly conductive floors in areas where people work with energized equipment. Specifiers can avoid liability by requiring electrical resistance between any two points (RTT) on the floor to measure at least 1 x 10E6 (1 million ohms) or above.

* The built-in resistor in ESD footwear slows the rate of static dissipation and protects the wearer from most electrical shocks.

** Standards include: Alliance for Telecommunications Industry Solutions ATIS-0600321, Electrical Protection for Network Operator-type Equipment Positions, Motorola R56, and FAA 019f.

- Attractive

- Moderately priced

- Yarns with low modification ratios can withstand heavy traffic

- Anti-fatigue and slip resistant

- Designs with random patterns provide longevity

- Easy to install and replace

- Can be installed over old floors

- Does not require conductive adhesive

- Easy and inexpensive to maintain

- Carpet measuring between 1.0 x 10E6 and 1.0 x 10E8 meets all industry standards

Cons

- Cannot withstand heavy loads or rolling carts

- Should not be installed in areas where solder and solvents are used

- Some designs can camouflage small tools or other items that fall on the floor

- Some conductive carpet does not meet resistance standards for end-user environments

When people walk across the floor, the carbon veins in a conductive SVT form an electrical bond between the floor and shoe soles, drawing static away from the human body to ground. To evaluate the conductivity of a floor, or its ability to transport charges to ground, we perform an electrical resistance test. Conductive vinyl easily measures under 1.0 x 10E9 ohms, the ANSI/ESD maximum acceptable measurement for electrical resistance, and usually tests in what we call the “Sweet Spot,” between 1.0 x 10E5 and 1.0 x 10E8, the ideal resistance range.

Note: ESD vinyl (dissipative or conductive) is a static-generating material. Vinyl does not inhibit static when people walk on the floor with regular static generating footwear. ESD vinyl meets ESD standards for charge generation only if every person in the space wears special ESD-protective footwear.

Unlike less expensive static-dissipative vinyl composition tiles (VCTs), SVT controls static without the need for periodic ESD-wax or polish treatments. Most manufacturers recommend cleaning methods that steer clear of finishes, polishes, or waxes. Since SVT is uniform throughout the thickness of the tile, high-speed buffing—what maintenance professionals call “burnishing”—is sometimes recommended for cleaning.

Over time, burnishing can damage the tile, making simple washing and low-speed buffing the preferred cleaning method.

Using conductive dry adhesives or fast-drying pressure-sensitive adhesives, low in volatile organic compounds (VOCs), some ESD vinyl can be installed in occupied spaces, right over the old floor, eliminating the need for shutdown during installation. For installers, leaving the floor in place reduces exposure to pre-existing dangerous contaminants like asbestos in older VCT tiles.

Risk Factors

To avoid unsightly installations, with gaps between seams, be sure the vinyl tiles will not shrink from plasticizer migration. Before selecting any vinyl tile, specifiers should ask:

- Where are the tiles manufactured?

- Is the material free of heavy metals, dioctyl phthalate (DOP), and bis(2-ethylhexyl)phthalate (DEHP) plasticizers?

- Does it meet all specifications for squareness and standards for electrical properties?

Must Be Used in Conjunction with Static-Protective Footwear

Once static builds on the body, the most conductive flooring material cannot bleed the charge quickly enough to prevent static from discharging when the person touches an electronic device—in other words, cannot protect electronics from the threat of random ESD events.

The conductive material in static-protective footwear—heel straps, toe straps, or special ESD shoes—forms an electrical bond between the wearer and the floor, preventing static buildup as the person walks across an ESD floor. With the use of protective footwear—and only in conjunction with special ESD footwear—conductive vinyl meets industry standards.

Without ESD-protective footwear, conductive vinyl is a static-generation liability.

As the floor cannot prevent static generation without ESD footwear, it’s suitable for use only in areas where special static-protective footwear is mandated and mandates are strictly enforced—generally true of most electronics manufacturing facilities. ESD vinyl is not suitable for use in 24/7 mission-critical call centers, dispatch centers, flight towers, or any other space in which people wear regular, non-ESD street shoes.

- Attractive

- Mono-lithic design creates clean, hospital-like appearance

- Moderate cost

- Durable

- Can handle high traffic and heavy loads

- Easy to install and repair

- Some ESD vinyl can be installed over old floors

- Snap-together options can be installed over subfloors with moisture problems

- In conjunction with ESD footwear, meets industry standards for electronics manufacturing and handling environments

Cons

- Static-dissipative (SDT) vinyl gains ESD properties from special wax or polishes

- Static-generating material: can only be used in conjunction with ESD footwear

- Unsuitable for use in 24/7 mission-critical or other end-user environments

In areas constantly exposed to heavy loads and high traffic, epoxy can be a very practical flooring choice.

Risk Factors

While epoxy coatings are ruggedly hard, the shiny slickness of the floor poses a slip and fall risk, and sounds tend to bounce off the hard surface and echo throughout the facility.

Epoxy is also easily scratched and difficult to repair.

Another downside: due to the high potential for field errors—improper mixing, spread-out, or unanticipated traffic during or immediately after the installation, for example—it is impossible to tell what an epoxy floor will look like or how well it will meet ESD electrical parameters until after it has been installed and fully cured.

Different Types of Epoxy

Inexpensive, first generation epoxies consist essentially of a black, carbon-loaded paint, creating a durable, no-frills, static-control surface.

Second-generation epoxies layer a colorized semi-conductive topcoat over a buried black primer (with embedded carbon) as part of the overall thickness of the coating, providing redundant paths to ground.

Newer technologies embed transparent conductive nanoparticles into a high-gloss topcoat, without the need for a conductive buried black primer—allowing for easy application, a wide array of colors, and superior static protection.

Epoxy May Not Meet ESD Standards

Properly installed, epoxies meet most ESD resistance standards. Unfortunately, most formulations of ESD epoxy coatings do not meet the new walking body voltage testing requirements per the ANSI/ESD S97.2 test method.

ESD epoxy will not prevent static without the rigid use of special static-preventive footwear. If people using the space wear normal street shoes, static-control epoxy floors will generate almost the same amount of static as their non-static-control counterparts.

- High gloss finish

- Seamless

- Durable

- Rugged

- Low cost

- Withstands high traffic and extremely heavy loads, including pallet jacks

- Used with ESD footwear, most high-quality epoxy products meet industry standards

Cons

- Poor ergonomics

- Slip and fall risk

- Sounds echo

- Easily scratched

- High potential for field errors during installation

- Difficult to repair—area under repair must be evacuated for several days

- Can be used only in conjunction with ESD footwear

- Unsuitable for use in 24/7 mission-critical or other end-user environments

- Many ESD epoxy coatings fail to meet walking body voltage requirements

The Flooring/Footwear Combination

As noted above, certain ESD floors—conductive SVT and epoxy, for example—prevent static only if grounded footwear is mandated and rigidly controlled. Electronics manufacturing facilities, often ESD-protected areas (EPAs), enforce protocols requiring static-protective footwear and, in some cases, require stationary personnel to wear wrist straps.

Outside the electronics manufacturing world, there is little clarity on performance criteria. This can get specifiers in trouble when they receive requests for “anti-static flooring.” Manufacturers’ spec sheets typically publish test measurements obtained in a walking test performed in controlled laboratory conditions—using static-control shoes in tandem with a grounded floor, as required by test method ANSI/ESD S97.2. This test does not indicate body voltages that would accumulate with street shoes, as are worn in most end-user environments.

The other test commonly referenced shows how much charge is generated on a subject, wearing test-specific shoe-sole covers, composed of neolite and/or leather (American Association of Textile Chemists and Colorists [AATCC] 134, Electrostatic Propensity of Carpets). Like S97.2, this test sheds no light on the implications for real-world environments in which people do not wear special ESD-protective shoes.

Flooring materials interact differently with different types of footwear

Tests show that static-control floors like epoxies, high-pressure laminates (HPL), and vinyl (conductive or dissipative) generate significant charges on people wearing most standard footwear. In real-world conditions, regardless of conductivity or grounding, epoxy, HPL, and vinyl are static-generating antagonists and should not be used as an ESD flooring solution.

Independent research by Dangelmayer Associates, Fowler Laboratories, and others have determined that EC rubber will inhibit static charges on people wearing most types of shoes.

Carpet tiles manufactured with conductive yarns, conductive pre-coats, and special backing will inhibit static generation on people wearing standard or static-control footwear. In mission-critical areas, EC rubber and static-dissipative carpet tile offer excellent static mitigation properties regardless of footwear.

Caveat: Resistance can vary in conductive carpet tile

There is a caveat: The manufacturing process of some ESD carpet tile produces significant variations in conductivity, with resistive measurements ranging from 25,000 ohms (2.5 x 10E4) to over 100,000,000 ohms (1.0 x 10E8)—sometimes within the same batch of carpet tile.

The first number, 10E4, is 2 orders of magnitude below the lowest resistance limits allowed by telecommunications and FAA standards, as noted above. Measurements below 10E5 are too conductive and could endanger people if they were to come into contact with AC-line voltages from servers or data storage equipment. Above 10E8, materials may not drain static as fast as it’s generated.

As far as specifiers are concerned, it is imperative to identify material with consistent electrical properties, for safety reasons as well as to ensure static-mitigation performance.

Electrical Resistance: The Sweet Spot

To avoid liability in end-user applications, it would be prudent to specify a resistance range that offers some margin for error at both ends of the spectrum. We recommend a resistance range we call the “Sweet Spot”—above 100,000 (10E5) and under 100,000,000 (10E8) ohms, as illustrated here.

Before specifying any carpet, the material should be tested for resistance to ground (RTG), as well as resistance between two surface points on the same tile (RTT). The logic behind requiring two tests is to weed-out both ineffective and overly conductive, unsafe materials. The supplier should also be asked to certify the resistive properties of the floor in writing after installation, and before it’s turned over to the owner. This is particularly important because lab tests are carefully controlled, and end users need to know how the flooring will perform in the real environment.

ESD Standards and Certification

Uniform industry standards have led to the creation of standardized technical specifications that match flooring application requirements. As already noted, electronics manufacturers require anyone handling static-sensitive parts to follow rigorous grounding protocols including footwear verification and testing. The electronics industry designates spaces where grounding is necessary as electrostatic protected areas (EPAs). Grounding protocols used in EPAs are outlined in ANSI/ESD S20.20, but this standard offers little instructional value for controlling static in real-world environments like data centers, 9-1-1 call centers, and healthcare facilities.

A close reading of ANSI/ESD S20.20 should eliminate the argument over whether static-dissipative or conductive flooring is better suited for static-control flooring. The requirements summary section, in Table 2, Section 8.2, sensibly encourages material selection based on multiple variables and several test standards—not based on a broad range of resistance, or on resistance designated simply as “conductive” or “static-dissipative.” The standard calls for specific numerical values. This is also the way an architectural specification should characterize electrical properties of flooring materials.

ANSI/ESD S20.20 also requires that the test subject not develop a body voltage charge in excess of 100 V. Body voltage is measured using test method ANSI/ESD S97.2.

In a recent ASHRAE study of static-control flooring for end-user environments such as data centers4, the organization recommended a maximum of 500 volts charge generation on people walking on the floor while wearing ordinary shoes.

Conclusion

To limit exposure from E&O claims, it is important to ensure that the specified floor meets the standards mentioned throughout this article. Post-installation certification is also important.* Most facility managers do not know whether they comply with ESD flooring standards, leaving it up to the ESD flooring specifier to guarantee compliance for them. The specifier—true or not—is assumed by the client to be the expert.

* To ensure flooring meets electrical safety specifications after installation, some manufacturers offer audits.

The ESD flooring industry will continue to grow, presenting significant challenges and opportunities for specifiers. As with any specialty, education will remain the most powerful tool. In the final analysis, all industry professionals should be working toward the same goal: providing the best flooring options for clients. To do this, the entire project team needs to appreciate what is at risk, speak the same language, and communicate openly.

Notes

- This is known as “Moore’s Law.” Intel Corp.’s co-founder Gordon Moore predicted the number of transistors on a chip will double about every two years.

- See David E. Swenson et al’s “Resistance to Ground and Tribocharging of Personnel, as Influenced by Relative Humidity” from the 1995 EOS/ESD Symposium Proceedings.

- This can be downloaded at esda.org.

- Footwear and flooring: charge generation in combination with a person as influenced by environmental moisture.

Updated from an earlier article, titled, “Specifying Static-free Floors” by Dave Long, published in the September 2011 issue of Construction Specifier.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.