Learn the differences between ESD solid vinyl tile and interlocking ESD tile. The post compares specs, installation, maintenance and intangibles.

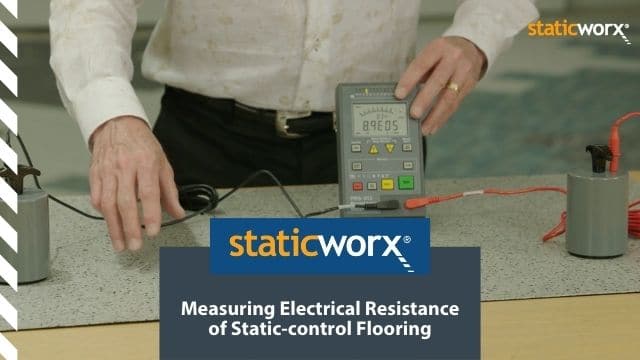

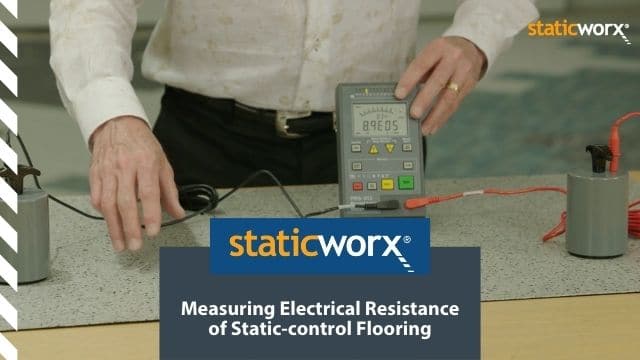

ESD Flooring Qualification Phase: Resistance Testing

8 min read, 2 min video

Not even close.

Let’s start with your mission. What are you doing and why are you doing it?

Hopefully your goal is to identify flooring options that meet standards like ANSI/ESD S20.20. To meet standards, you need to utilize standard test methods. When it comes to ESD flooring, the test method you need to follow is ANSI/ESD STM 7.1-2013. Do you have a copy of this test method? If you don’t have a copy, you can order it here on ESDA.org.

Don’t even think about making decisions without first testing the material, following procedures in this test method. It isn’t as simple as measuring samples right out of the box. Let’s go through the entire process step by step:

There are two distinct phases to evaluating and selecting ESD flooring:

- The qualification phase

- the acceptance phase.

In this post, we’ll cover the qualification phase.

Excerpted from ANSI/ESD S20.20

7.3 Product Qualification Plan

A Product Qualification Plan shall be established to ensure that the ESD control items that have been selected meet the requirements in the plan. The test methods and required limits are located in the product qualification columns in Tables 2 and 3. Product qualification is normally conducted during the initial selection of ESD control items. Any of the following methods can be used: product specification review, independent laboratory evaluation or internal laboratory evaluation…

Table 2: Personnel Grounding Requirement

| Technical Requirement | Personal Qualification Test Methods/Required Limits | Compliance Verification Test Methods/Required Limits | ||

| Footwear/Flooring System (Both limits must be met) | ANSI/ESD STM97.1 | <1.0 x 10E9 ohms | ESD TR53 Footwear Section | 1.0 x 10E9 |

| ANSI/ESD STM97.2 Peak | < 100 volts | ESD TR53 Flooring Selection | 1.0 x 10E9 | |

Table 3

| Technical Requirement | ESD Item | Product Qualification Test Methods/Required Limits | Compliance Verification Test Methods/Required Limits |

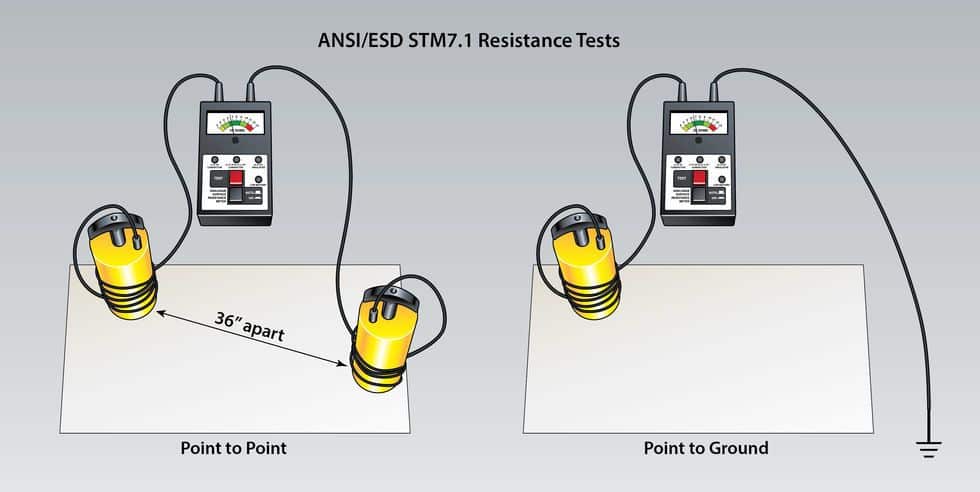

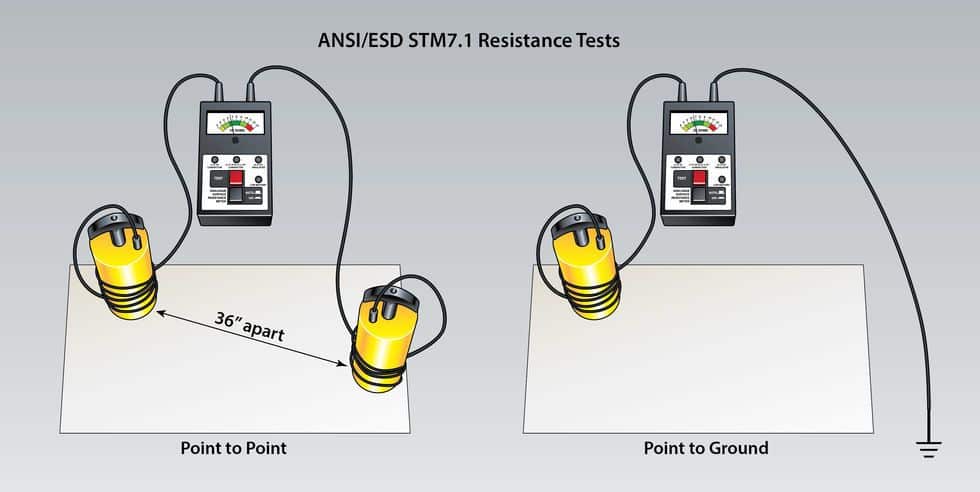

| EPA | Flooring | ANSI/ESD STM7.1 | Point to Point <1 x 10E9 ohms |

| Point to Groundable Point <1 x 10E9 ohms |

Please note, this is qualification for EPA (ESD Protected Area). The additional information in the tables is not pertinent to flooring.

– Electrostatic Discharge Association, S20.20

The qualification phase requires you to install 12″ x 24″ samples of the proposed flooring on an insulative support material like rigid plastic sheet stock. You should install the test specimen on the support sheet in the same way the flooring would be installed in your factory. If the flooring uses an adhesive, then you need to secure it with the specified adhesive.

Most ESD flooring is sold in tiles or sheets. You must create one seam in your 12″ x 24″ sample to duplicate the kind of seam that might exist on the floor after it is installed. This will enable your tests to measure resistance values as current moves from one tile or section to the adjacent tile or section.

Last and most important: The installed samples must be conditioned at 12% +/- 3% humidity for at least 72 hours before the tests begin. The tests must be performed inside the 12% +/- 3% environment.

Why must the humidity be so low?

We need to eliminate the possibility of high humidity influencing the test results. Many materials are made with chemicals that gather moisture from high humidity, increasing the conductivity of the flooring material. In most cases, moisture-gathering chemicals become less effective over time or leach out of the material, raising its resistance. Other flooring materials require special waxes that perform well at high humidity and poorly at low humidity. Conditioning the samples at low RH will reveal these deficiencies.

Before starting qualification testing, ask the following questions:

- Does your meter have two voltage settings of 10 volts and 100 volts?

- Does your meter produce these voltage +/- 5% while under load?

- Does your meter measure at least from 1.0 x 10E3 to 1.0 X 10E10 ohms?

Resistance to Ground Testing (RTG)

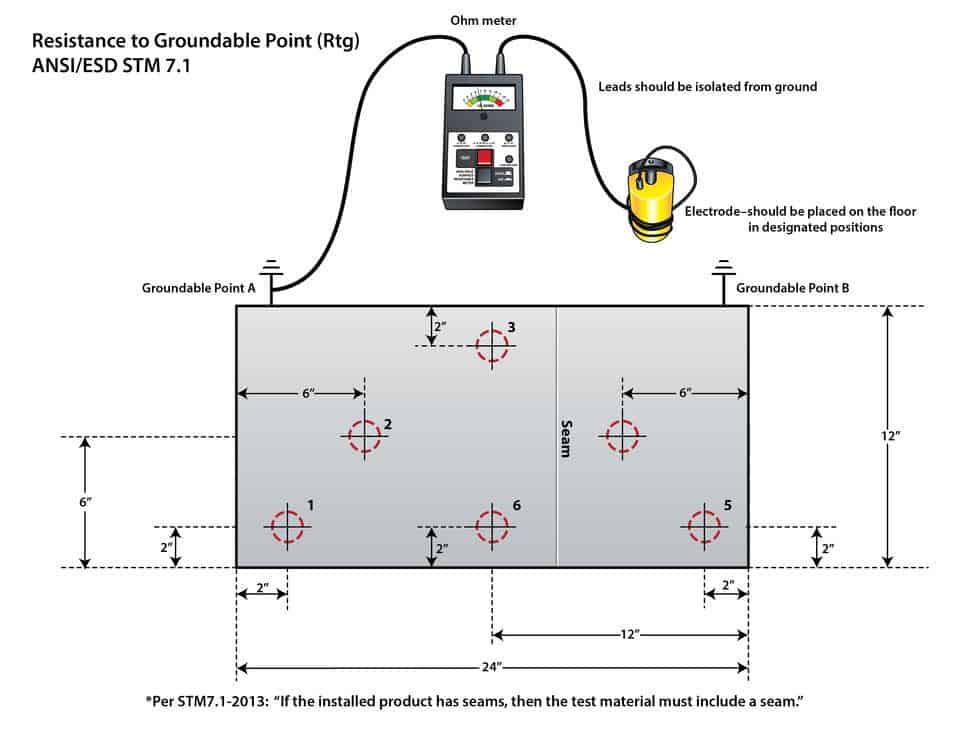

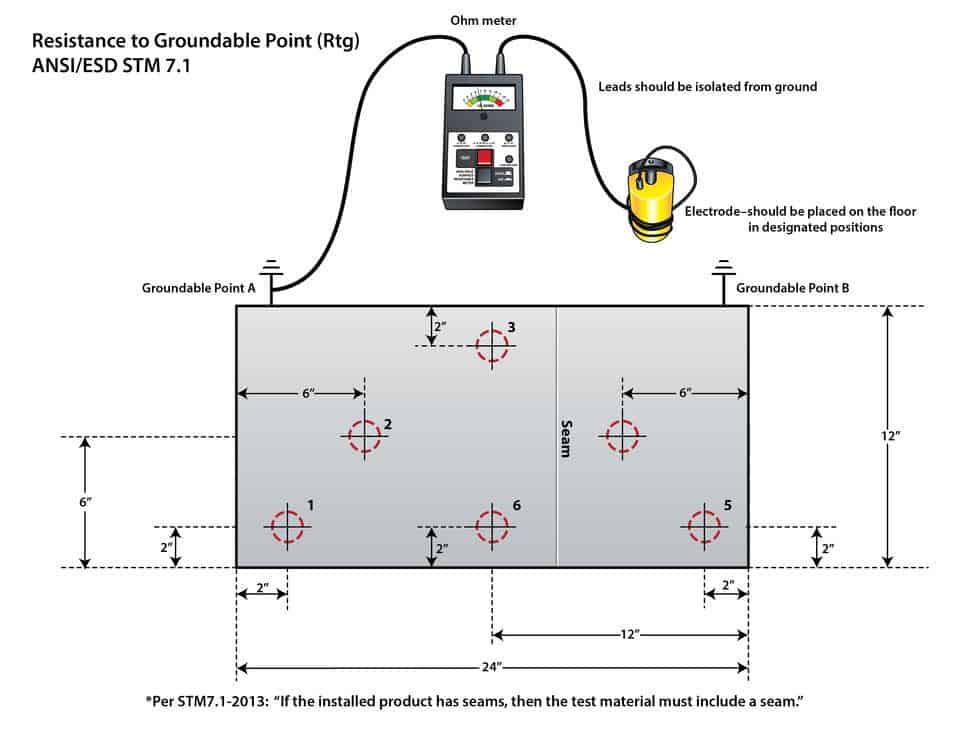

To qualify a flooring product, you will need five 12″ x 24″ samples with two groundable points per sample. The samples should be numbered from 1 to 5. All five samples must be conditioned for the full 72 hours at low humidity. Each sample will be tested 6 times from both ground points per the diagram below. This will yield 60 measurements in total.

Note: If you look closely at the diagram below, you’ll note that some of the test points are very close to the ground locations; some are in the opposite corner; and at least 2 tests will probably cross the seam you created when you prepared the samples. These are important details because the purpose of this test is to determine, among other things, if the floor has any shortcomings under different circumstances. One shortcoming might be wide variances across seams vs resistive properties within the same tile.

Point to Point Resistance Testing (RTT)

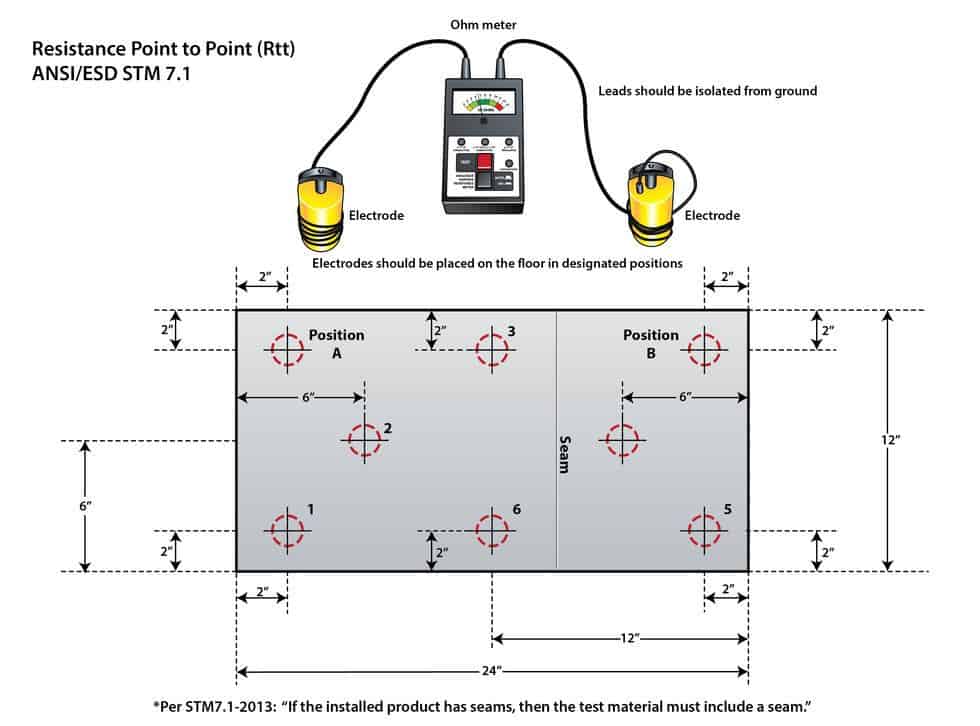

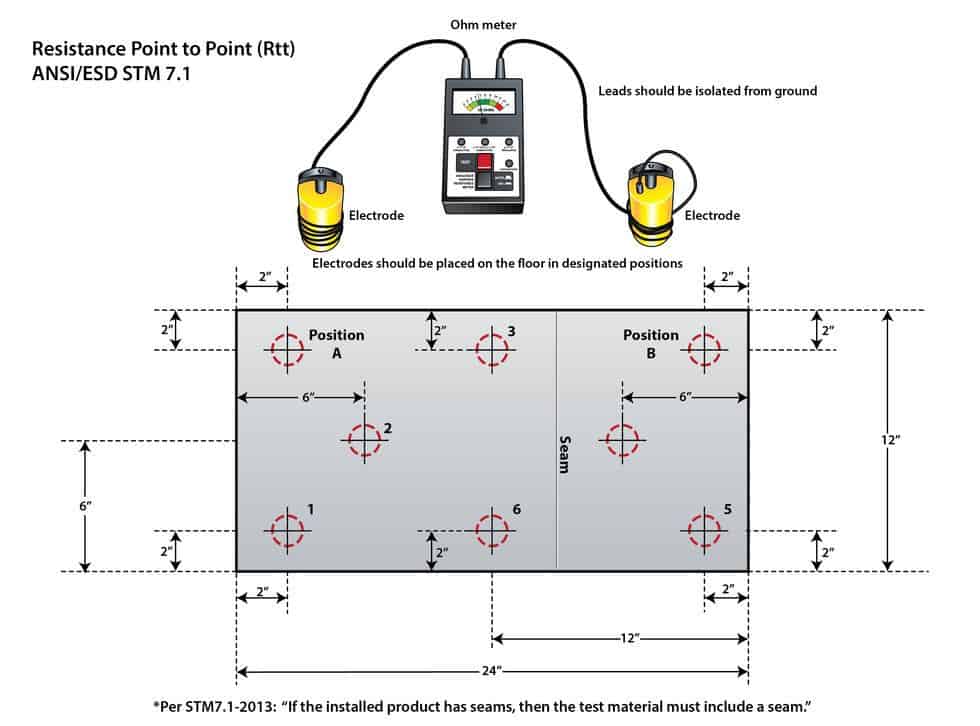

RTT testing examines the surface of the floor. The qualification phase of RTT testing will tell us if the surface of the floor is more or less conductive than the resistance through the thickness of the floor. Like the previous tests, each sample is tested 6 times from 2 fixed probe locations. The fixed probe locations are marked as position A and B in the illustration below.

This test will tell us what might happen if the floor were inadvertently grounded by equipment placed on top of it. In most cases resistance values are a cumulative measurement involving a less conductive surface and a more conductive adhesive or underlayment. However, the surface of some materials is more conductive than the underlayment the material is bonded to. In this scenario, the surface of the floor could form a ground circuit with a piece of nearby energized equipment, with much less resistance than intended. Standards like FAA 019f call out this and other surface tests for this very reason.

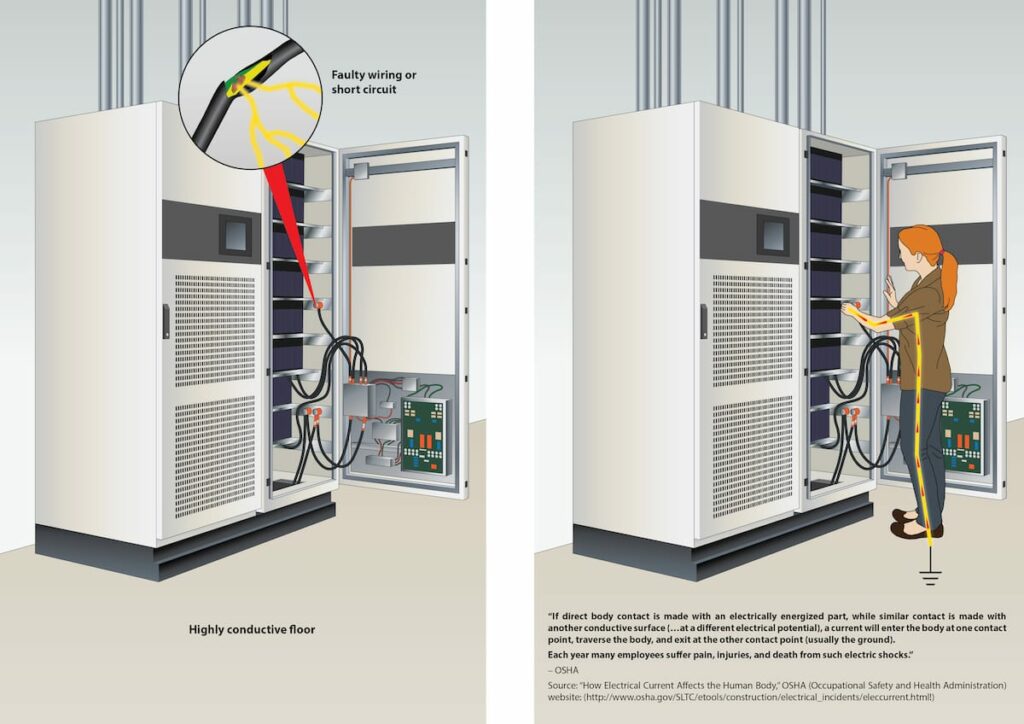

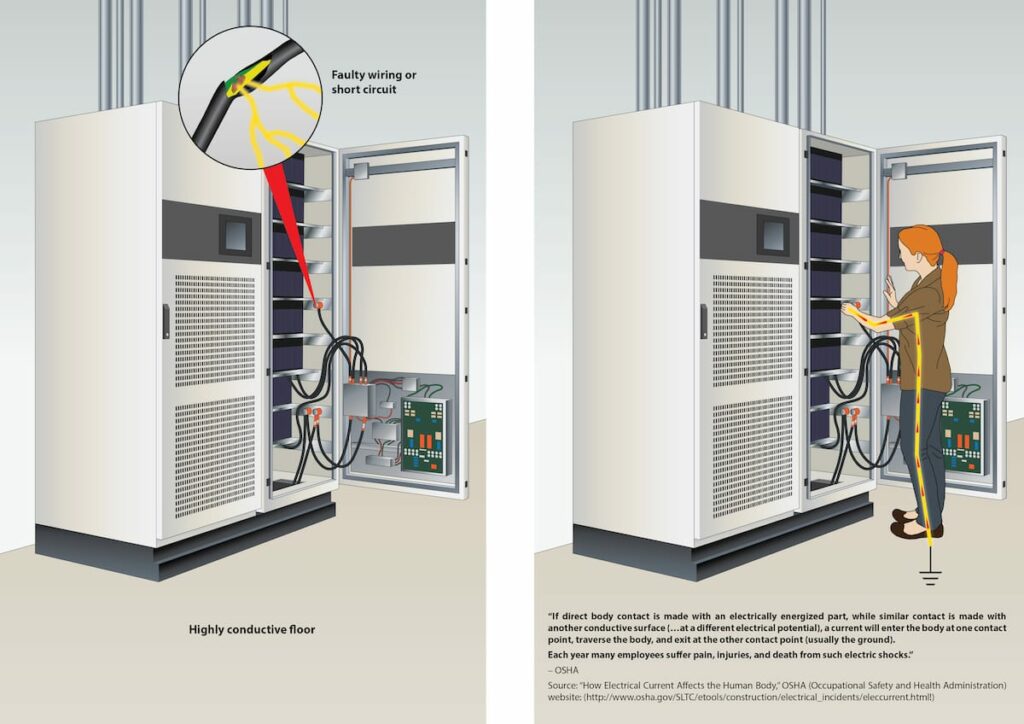

We never want an ESD floor to become grounded at a lower electrical resistance than a particular standard prescribes.

To satisfy safety concerns, we need to account for intended and unintended ground connections.

About StaticWorx, Inc

All StaticWorx posts are written by our technical team and based on industry standards and specifications, test data, independent lab reports and other verifiable data. We provide ESD training and offer CEU credits to architects. If you’re interested in an ESD training session or our architects’ ESD workshop, give us a call: 617-923-2000.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

More Blog Posts

To maintain performance, ESD floors require specially formulated products. We offer tips on what to consider when choosing cleaning supplies.

Static-dissipative floors transport harmful static charges to ground. Dissipative is also a term for flooring with a specific, measurable electrical resistance.

StaticWorx recognized as one of the fastest growing private companies in the U.S. 2023 marks StaticWorx fourth appearance on Inc. 5000 list.

Conductive and dissipative flooring protect electronics by transporting charges to ground, conductive at a quicker rate, dissipative slower & more controlled.

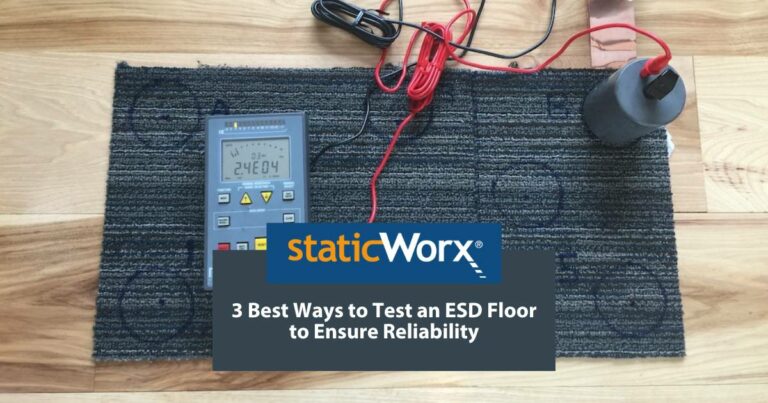

We explain the 3 main ways to test an ESD floor: Electrical resistance; body voltage & ESD audits, with advantages and reasons for each.

Three critical factors—application, industry standards & footwear—help you choose the best ESD floor, while ensuring the safety & efficiency of your operations.

StaticWorx Founder and President Dave Long shares three of his recommended reads: Quit, How to Change, and The Goal.

There are leadership qualities StaticWorx strives to embody every day, with every product, throughout each project.

No matter how you slice and dice a project, an ESD floor is a major investment. This blog post examines five ways to keep undue costs down.

What’s the difference between static control and static resistant? Or anti-static flooring? Find out more in our blog post.

A major part of any ESD control program is getting proper flooring in place. How can one replace a floor without generating any debris? Learn more.

A well-designed, comprehensive, fully realized program is a must for manufacturers serious about ESD control. Learn why ESD programs fail.

ESD Floors should never be specified based on the descriptive terms conductive or static dissipative. Always base ESD specs on verifiable metrics. Find out why.

To comply with relevant ESD standards, test electrical properties using methods outlined in ESD S20.20. For best results require testing by an independent lab.

If the vapor barrier fails to adhere to the subfloor, tiles will lift. Bond test and manufacturer oversight are crucial to ESD floor installation success.

Blog Post: Conductive and Static-Dissipative Flooring: What’s the Difference?

The Layperson’s Answer

What’s the difference between conductive and static-dissipative flooring? Facts, analogies and images illustrate the difference in easily understood terms.

Qualifying an ESD floor helps ensure you get the floor you paid for. Find out why you should always qualify according to ESD S20.20

Will bare concrete control static? Learn why concrete floors are unreliable & what precautions to take if you must work on a bare concrete floor.

A look at how the StaticWorx cartoon, 'Conductive Flooring Does Not Mean Antistatic Flooring,' was conceived and created.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.