Our History: A StaticWorx Timeline

StaticWorx was conceived over the summer of 2007. Frustrated by the confusion and lack of information in the marketplace, Dave envisioned an ESD flooring company focused on transparency—with direct communication between the customer and true brand supplier.

In October 2007, StaticWorx moved into a 300 sq./ft. office above a Starbucks café in Newton, Massachusetts. Two months later, the economy crashed, with reverberations affecting businesses for years after the Great Recession finally ended. Thanks to our expanding network of architects and designers, facility managers and engineers, contractors, flooring installers, and property owners, StaticWorx managed to stay afloat. In 2023, we’re proud to say, Inc. 5000 recognized StaticWorx as one of the fastest growing companies in the U.S., our fourth appearance on that list.

Today, from our offices in Williston, VT, and Washington, D.C., and our warehouses in Vermont, Georgia, and southern California, we provide over two million sq./ft. of ESD flooring per year to businesses and government facilities across the globe.

Here—with thanks to our amazing partners and clients—is the StaticWorx timeline, the highlights of our journey.

- October 2007

-

November 2007

Begins warehousing in Georgia

To provide clients with better service and faster delivery, StaticWorx signs on with a contract warehouse and begins storing and shipping ESD flooring materials from Georgia. Early on, warehoused products consist primarily of carpet and adhesive. By 2008, StaticWorx is warehousing a complete line of static-control flooring products and adhesives.

-

December 2007

Expands Into Mexico

With explosive growth fueled exclusively by word of mouth, the company expands west from New England, and moves into the emerging Mexican market. As electronics manufacturing grows, Mexico plays an increasingly important role in our business development strategy. Our first Mexican project is a 200,000 sq/ft installation for Rockwell Automation in Monterrey.

-

December 2007

The Financial Crisis

December 2007 marked the onset of a global economic crisis known as the “Great Recession.” Tight credit and weakened demand for their products hammered small business, with the smallest firms suffering losses far in excess of large corporations. Small construction companies, among the hardest hit, saw a 19.4% decline in employment between 2007 and 2009. Though the recession officially ended in 2009, recovery was long and slow, and its effects lingered for years.

Data from U.S. Federal Reserve and Federal Reserve Bank of New York

-

March 2008

Launches EC Rubber

Developed exclusively for StaticWorx, EC Rubber is the first conductive ESD rubber floor to provide a lifetime static protection warranty, regardless of the footwear worn in the environment. Our first truly green product, EC Rubber is awarded the prestigious GREENGUARD GOLD certificate, a stringent certification for low-VOC emissions and indoor air quality.

-

June 2008

Launches AmeriWorx Vinyl Tile

Poor quality controls in ESD vinyl materials produced offshore result in off-sized tiles that shrink due to filler content and plasticizer migration and continue to shrink after they’ve been installed. These low-quality materials and ugly installations frustrate installers and end users, fueling a burgeoning demand for products made in America. AmeriWorx ESD tiles, produced entirely in the U.S., provide a clean, hospital-like appearance, while meeting all industry standards for electrical performance.

-

October 2008

Begins warehousing in California

To service an expanding client base in the western parts of the U.S. and Canada, on the West Coast, and in Mexico, StaticWorx opens a warehouse in Los Angeles. This enables the company to get products to building sites faster and, in some cases, provide same- or one-day delivery.

-

May 2010

NanoMarkets projects sales of ESD products to exceed $8 billion/year by 2015

NanoMarkets, a leading analyst in the electronics industry, reports on the miniaturization of electronic circuitry in computers and other electronics, including handheld devices, warning that as these powerful devices decrease in size, they become much more vulnerable to electrostatic discharge (ESD). NanoMarkets projects sales of ESD products to exceed $8 billion by 2015.

-

June 2010

Buildings Magazine names EC rubber Top Money-Saving Product

Staticworx EC Rubber is featured in Buildings Magazine as one of 81 top money-saving building products. The article states: “EC Rubber is the first conductive rubber floor that provides anti-static protection for any environment. The flooring is unaffected by aging, traffic, or humidity; it’s oil, grease, and chemical resistant; and saves on maintenance and product replacement costs. [An independent lab] calls it the only static-resistant product that inhibits static generation regardless of footwear.”

-

March 2011

Switches from conductive to static-dissipative carpet

In response to revised national grounding standards in the communications industry, aimed toward protecting people who work around electrified equipment, StaticWorx switches from conductive to static-dissipative carpet. Static-dissipative carpet grounds static charges as effectively as highly conductive carpet, which is prohibited under the revised standards by organizations such as the FAA (FAA 019f), Motorola (R56), ATIS (0600321), and the National Fire Protection Association (NFPA 99).

-

June 2011

Launches third-generation EC rubber

Associations, universities, labs, consultants, and clients as diverse as ASHRAE, MIT, Dangelmayer Associates, and the ESD Journal have found that conductive rubber flooring offers the lowest charge generation properties of any type of ESD flooring available today. EC rubber is the recipient of both the prestigious GREENGUARD GOLD certificate for indoor air quality, and the Seal of Approval by ESD Journal as the only fault-tolerant ESD flooring product. Eclipse Rubber meets all domestic and international standards including ANSI/ESD S20.20, ANSI/ESD STM 97.1 (system resistance), ANSI/ESD STM 97.2 (body voltage generation), DOD 4145.26-M (munitions handling), and NASA-grade, clean-room requirements.

-

March 2012

Named to Boston Business Journal 2012 Pacesetters list

This award marks the company’s third consecutive appearance on the BBJ Pacesetters list—a list of the region’s fastest-growing privately held companies.

-

August 2012

Named to the Inc. 500/5000 List for third consecutive year

Inc. Magazine’s 500/5000 list honors the fastest-growing privately-held companies in the U.S. “Fast growth at any time is a big achievement; fast growth during the past few years is just short of miraculous,” said Inc. Editor Jane Berentson. “The Inc. 500/5000 consists of these just-short-of miraculous companies, the ones that through ingenuity and ambition have increased revenue, hired employees, and grown fast in difficult economic times.” This marks the company’s third appearance on the Inc. 500/5000 list.

-

February 2013

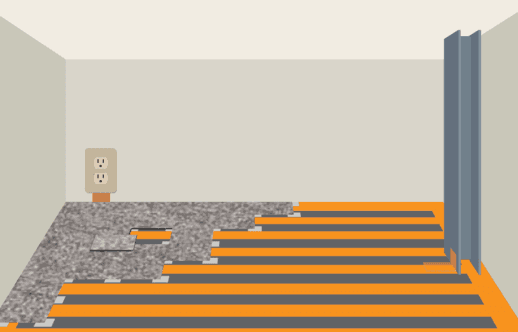

Launches GroundBridge glue-free installation system

A lightweight material composed of conductive cellulose, this conductive, glue-free grounding method enables flooring installations over any existing subfloor. Installation is clean, easy, and fast, with no VOCs. A floating floor can be created with ESD carpet tile simply by rolling GroundBridge strips over the existing floor, then joining the corners of StaticWorx ShadowFX ESD carpet tiles, using dimensionally-strong, self-adhering TacTiles®

-

July 2013

Partners with VersaShield – rolled barrier to protect concrete from moisture

StaticWorx is contacted by a multi-location flooring contractor seeking an ESD flooring material – vapor barrier combination that can be installed in occupied spaces without disrupting the workforce. One month later, StaticWorx and Halex Corporation (now Lovara by GCP Technologies) begin a long-term relationship, offering clients a one-stop solution warrantied for ESD protection and moisture vapor mitigation.

-

August 2013

Launches Eclipse GF self-adhesive rubber sheet floor

The first moisture-resistant, self-adhesive rubber sheet floor, EclipseGF has a pre-applied, vapor resistant, self-adhesive backing. This glue-free installation allows for immediate traffic, without the long drying time associated with adhesives. Appropriate for most applications, EclipseGF is specifically targeted to cleanrooms, electronics manufacturing, and 24/7 mission-critical spaces, where shutdowns cannot be tolerated.

-

October 2013

Moves corporate office to Waterbury, VT

After six years in an exciting, fast-paced environment, just minutes outside the city of Boston, StaticWorx moves to its new home in Waterbury, Vermont. Spectacular views of the Green Mountains from the windows of the 18th century farmhouse lend an air of serenity to the busy, sometimes chaotic, days in the StaticWorx offices. The clean mountain air, along with a state-wide dedication to sustainability and community life, underscore the StaticWorx mission and reflect our corporate values, making Vermont a terrific place to work—as well as to live.

-

March 2014

Launches ShadowFX SD modular carpet tile

ShadowFX modular carpet tiles mimic the organic design of nature. Varying colors and patterns within each tile allow for easy, non-directional installation, hide wear, lengthening the lifecycle of the carpet, and eliminate the need to match dye lots. ShadowFX SD provides excellent static protection and meets all national and international standards for performance and safety, including ANSI/ESD S20.20, FAA 019f, Motorola R56, and ATIS 0600321. With its natural look, sustainability, and Green Label certification, ShadowFX quickly becomes a favorite among architects.

-

November 2014

Launches Shadow FX PosiTile, compatible with Tate Raised-Access Floors

With its surface-hugging backing, ShadowFX PosiTile lays flat without any dots or strips of glue. Positioning buttons are welded ultrasonically to the underside of ShadowFX tiles, creating a precise one-to-one match between the tile and the floor panel, allowing for quick, easy swapping of carpet tile, and eliminating need for shutdowns and work interruption. Meets key industry safety guidelines, including Motorola R56, ANSI/ESD S20.20, and ATIS 0600321.

-

March 2016

Launches AmeriWorx Rox ESD Vinyl Tile

With its unique, rock-like design inspired by nature, AmeriWorx Rox was created with architects in mind. Multi-pigmented conductive granules introduced in the manufacturing process provide splashes of color resembling rocks in this aesthetically pleasing, highly functional vinyl tile. Like all StaticWorx ESD flooring products, AmeriWorx Rox provides permanent static protection and meets all industry standards for electrical performance and safety.

-

October 2016

Begins renovation of 18th century building housing StaticWorx corporate office

A year after the move from Massachusetts, the company settled in its new digs, it’s time to begin renovations. Emerging structural issues and changes mandated by the state to meet ADA requirements turn what begins as a minor renovation—repurposing an adjoining barn as a warehouse and adding a small living space for overnight visitors—into a major overhaul.

-

January 2017

Opens Office in Washington D.C.

A new sales office in Washington, D.C., gives StaticWorx a physical presence in this thriving region, home to the many government facilities and contractors we serve.

-

February 2017

Launches ESD Planx

StaticWorx ShadowFX ESD Planx modular carpet tiles—another architect-inspired product—simulate the appearance of wood planks, creating natural-looking floors that mimic the geometry and flow of surrounding spaces. Scale and directionality also provide an expanded range of design options. Like all StaticWorx ESD flooring products, Planx meets all standards for performance and safety.

-

May 2017

StaticWorx ESD vinyl tile and adhesive receive FloorScore certification

AmeriWorx and AmeriWorx Rox vinyl tile, and StaticWorx conductive adhesive receive FloorScore certification. An independent certification program, FloorScore tests and certifies hard-surface flooring materials, adhesives, and underlayments for compliance with stringent indoor air quality emissions. The certification qualifies products for green initiatives, including LEED v4, WELL, BREEAM, and CHPS.

-

August 2017

Releases first cartoon short to animate a complex technical issue

Conductivity and static generation are two of the most confusing—and misunderstood—of all ESD terms and technical issues. Most laypeople believe if a floor is conductive it will eliminate static electricity. In fact, a conductive floor can generate enough static to wreak major havoc. Rather than bore listeners with a long, complex technical explanation, we animated the problem, cause, and its solution. We hope viewers will find the cartoon both entertaining and enlightening.

-

April 2018

Launches StaticWorx Learning Center Website

In keeping with our knowledge-oriented approach, we’ve launched a new multi-media site, packed with comprehensive, up-to-the-minute information on static electricity. The learning center, which took nearly a year to build and features podcasts, videos, articles and blog posts, is geared specifically toward architects, engineers, building owners/facility managers, and flooring installers.

-

October 2018

StaticWorx FloorScore certification is renewed

StaticWorx qualifies for renewal of its FloorScore® Private Label Certification.

-

March 2019

The Launch of Static Bursts, the First StaticWorx Podcast Series

Static Bursts is made available on iTunes, Google Play, SoundCloud, Spotify, TuneIn and many other platforms. Find out more about the podcast on the Static Bursts page.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.