Moisture problems are the #1 cause of failed flooring installations....

Read More

Static Bursts (Ep #3): Why Resistance Tests Alone Are Not Enough to Properly Qualify An ESD Floor

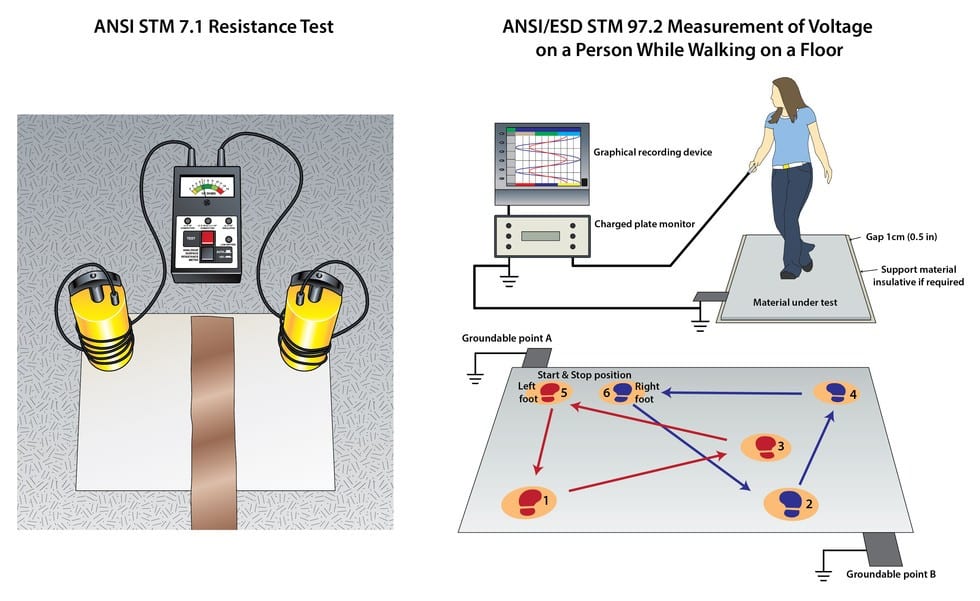

Prior to 2014, the standard for qualifying an ESD floor, based on ANSI/ESD S20.20, required testing electrical resistance to ground and system resistance, which includes the floor, adhesive, and test subject wearing ESD footwear. If the floor measured below 1.0 x 10E9 ohms and below 3.5 x 10E7 ohms for system resistance, it passed the qualification testing. If the floor passed both types of resistance tests, it was assumed to meet the standard for static generation – ≥ 100 volts. (Testing for static generation was required only if the floor failed these tests.)

However, certain types of conductive flooring passed both tests and still generated significant static charges on people wearing certain types of ESD footwear. In 2014, changes to S20.20 acknowledged this flaw and qualification requirements were modified to include tests for body voltage (charge generation).

Today, to properly qualify an ESD floor, you must test resistance to ground, point to ground resistance, and system resistance. You must also test for walking body voltage. Tests must be performed in a controlled environment at 12% RH +/- 3%.

- System resistance and charge generation tests must be conducted with the test subject wearing ESD footwear.

Because some flooring materials perform differently with different types of shoes, qualification tests must be conducted with every type of footwear allowed in the space. If employees will be required to wear ESD shoes and visitors will be given conductive heel straps, for example, the floor must be tested with ESD shoes and heel straps.

Episode Highlights: Why Resistance Tests Alone Are Not Enough to Properly Qualify An ESD Floor

- Resistance tests alone do not predict the floor’s propensity to generate static. Some highly conductive floors generate a significant amount of static on people wearing certain types of footwear.

- To meet qualification standards outlined in ANSI/ESD S20.20 – 2014, you must perform three different resistance tests as well as testing for charge generation.

- Tests include: Point to point resistance (STM7.1); Point to ground resistance (STM 7.1); System resistance (STM97.1); Charge generation/body voltage generation (STM97.2)

- To properly qualify a floor, tests should be done in a controlled environment at 12% humidity +/-3%.

- Different floors perform differently depending upon the footwear used. System resistance and charge generation tests must be performed multiple times with the test subject wearing every type of footwear to be allowed in the space.

“You’ll see things when you look at spec sheets like “exceeds R56,” “exceeds FAA 019f.” You can’t exceed those standards, and the reason you can’t exceed them is they prescribe a range. There’s a minimum and a maximum. How do you exceed that?”

We’ve made it easy to subscribe on your favorite platform!

Welcome to Static Talks. I’m your host, Dave Long, founder and president of Staticworx. We make static-control flooring and our podcast will discuss the threat static electricity poses to your business and how to address those risks.

Rick, remember that question this morning about the PU coating on the ESD vinyl tile?

Rick: Yes.

Dave: And the testing?

Rick: I do.

Dave: Back in 2014, the ESD Association revised a standard called ANSI/ESD S20.20 and one of the parts of that standard calls out for requirements in ESD flooring. Those requirements have to do with several different parameters. So, when we look at flooring, there are several properties we’re actually hoping we can identify so we can determine if we’re going to be able to achieve what we need to with our ESD program.

So one of the properties we look at is electrical resistance. We measure that using an ohmmeter. Historically, when flooring has been qualified and certified after installation, the method of doing that was to take an ohmmeter and take two of what we call NFPA probes, which are basically a couple of five pound weights with a rubber, elastomeric material that’s conductive on the bottom of them and we set these probes down on the surface of the flooring, and we measure the resistive properties between two probes. Then we take one of the probes, disconnect it from the ohmmeter and instead make that connection to a ground source, and measure the resistive properties from the probe that’s still connected to the ohmmeter through the flooring to the adhesive to ground. We call that test a resistance-to-ground test.

Before 2014, if the floor measured less than 10E9 – which is a billion ohms – and then we did a second resistive properties test, which amounted to standing on the floor in place of the probe… So, picture this: instead of having a probe on the floor, you’re standing with your ESD heel straps or ESD shoes, and you become the probe. So you take the test lead from the ohmmeter, you hold it between your fingers, the other lead is attached to ground, and we make a measurement that includes your body, your ESD footwear, the floor, the adhesive, all the different items that are used to make that connection to ground. So that test is called the system resistance test and that test standard ends in 97.1. So it’s ANSI/ESD STM97.1.

Before 2014, you would do these two tests. You would test the floor with the five-pound weights, and you would test the floor with a person essentially acting as a probe, and if the five pound weight test measured under 10E9 and if the system resistance – which included the person in their heel straps – measured less than 3.5 x 10E7, you would say that floor now qualifies for use in an ANSI S20.20 compliance program. That was the end of it.

Rick: But it sounds like that type of test does not actually produce a useful measurement, right?

Dave: The major downside to relying on that test is that you’re using resistive properties as a predictor of whether or not when a person walks on the floor, they’ll generate a static charge. Now, we measure static charges in volts, not ohms. So right away, we’re using a test that measures a different property, using a different unit of measurement, to predict a property that kind of has nothing to do with resistance. And I guess the way we want to describe this as it played out, we would often see conductive floors – which measure less than one megohm in any location on the floor, whether it was an epoxy floor, or whatever type of floor the client might have – but under certain circumstances, even though the floor measured in the conductive range, when a person would walk on the floor, with their ESD footwear, they would generate, in some cases, hundreds or even over 1000 volts of static electricity.

Of course, that doesn’t make sense to some people because they’re thinking if the floor’s conductive and you’re wearing ESD footwear, how’s that possible? Well, remember one thing: heel straps cover your heel. If you were to capture a person’s walking motion in slow motion, what you would actually notice is that sometimes the forefront of their foot is making contact with the floor, sometimes their heels are, and depending upon their gait, it’s even possible that for a moment in time, there’s actually no contact at all with the floor. Because of the way heel straps work – you’ve seen heel straps, right?

Rick: Right.

Dave: Okay, so a heel strap, because it’s only covering the heel, other than where the heel strap is covering your shoe the rest of your shoe is an electrical insulator. So when that electrical insulation portion of the shoe makes contact with the floor, it generates a static charge. If you happen to do that, at the same moment as you stop so that the heel strikes the floor, that charge would immediately go to somewhere – hopefully – fairly close to zero. But because walking is moving, you’re actually generating charges and, sure, they’re discharging, but you’re generating what we would call spikes of voltage.

Rick: When measuring walking body voltage, is that a measurement of the flooring itself or of the footwear worn by people in that room?

Dave: When we perform a walking body test to measure the static charge on people, one of the things we’re actually learning is not just whether the floor does what it’s supposed to do, but whether the ESD footwear that they’re using does what it’s supposed to do, and more importantly, whether the ESD footwear and the floor actually work with each other.

Over the last 15 years, we’ve been working with a third party testing lab that we send flooring to so that they can test it in a controlled environment. And by controlled environment, I mean an environment where they condition the flooring materials – and the footwear, for that matter – at 12% relative humidity. The reason for the 12% relative humidity is that in all these ESD standards that you’ll hopefully either already have, or hopefully be obtaining based on our discussion today, the first thing you will learn about flooring for removing static electricity is that you need to qualify the properties of the floor so that you can then make a decision based on that flooring working under a low humidity condition. Because when you install the floor, it’s very likely that on any given day the relative humidity could be 20% or it could be 70%, and as a result of fluctuating humidity in a lot of these factories, you could potentially qualify a floor in your factory, not in a controlled environment, on a day when the humidity is high, and assume that your flooring meets the qualification standards of the ESD Association, and not ever know that on days when the humidity is low, your flooring isn’t doing what it’s supposed to do.

The way the S20.20 document handles that potential, I guess you could say pitfall, is they want you to first qualify the floor, and by qualify they mean send it to a lab, or if you happen to have the right humidity chamber to make these sorts of tests which most people don’t have, sure you can do it yourself, but you need to know what that flooring will do at low humidity using the footwear that you plan to use in your factory. So let me just back up a little bit because this is kind of an important point.

Suppose you’re going to buy flooring, and you decide that you’re going to get brochures and literature from several different manufacturers. Every one of those brochures is probably going to have some statement or list of performance parameters that will include what we call walking body voltage and resistive properties. And if you look at the walking body voltage properties, I don’t know a flooring manufacturer in existence that doesn’t state that they meet ANSI/ESD S20.20. However, if you look more closely, what you’ll discover is they don’t tell you what type of footwear that the flooring met the hundred volt maximum of ANSI S20.20 with. They just tell you they meet it [the standard]. What we’ve learned – kind of the hard way, because like any manufacturer, we’re always trying to make sure that we stay ahead of things – is that certain footwear works better with certain floors.

Rick: Alright, so we know that even if ESD footwear is being worn consistently, the particular type of ESD footwear will have an influence over the results of your compliance testing. Can you offer any real-world examples of this?

Dave: So for example, one of the tests we did a few years ago was with an interlocking plastic floor that we thought looked like it was a very, very good product, and the literature actually stated that the floor generated less than 25 volts on a person per the ANSI test method for walking body voltage. However, when we did the test at the third party testing lab, we generated 700 volts on that floor, and the reason we were able to get 700 volts is we happened to choose to use ESD heel straps for the test. The reason we did that was, the particular customer we were doing the test for asked us to make sure that we tested the floor with the type of footwear that they planned to use. And they didn’t plan to use the ESD shoes, which actually provide a full sole contact area that has conductive properties. Like I said earlier in this discussion, heel straps only cover the heel of your shoe. So when you test the floor, you need to test it not only with the footwear that you will be using, but also the footwear you might give to a visitor.

This particular company wanted us to test it [the floor] with heel straps and we did. That 25 volts generated with a particular ESD shoe became 700 volts, not because the floor we tested was any different than the one the manufacturer tested, but because we tested it with footwear that essentially would not work with that floor. And that’s a big problem because, in my travels around the world, most companies – particularly electronics manufacturing of circuit boards and any kind of high volume electronics – they have a tendency to give their employees heel straps as their ESD footwear, not ESD shoes. So a set of heel straps probably cost somewhere in the vicinity of $7-8, a pair of ESD shoes could cost $150, and because of the obvious need to control costs, you’re going to notice that most factories use heel straps. So whenever we perform any type of testing on ESD flooring, we’re always going to be including heel straps and several different types of ESD shoes in our test so we can tell the client, this is what you can expect with this, this is what you can expect with that.

Unfortunately, when you read the literature, it doesn’t tell you that and I’m talking about anyone’s literature – ours included; otherwise the information would get too crowded. So normally when we work with a client, what we will do is we will also send them the test reports. That way they have the opportunity to look and see if they can confirm that the type of footwear they’ll be using was in that test.

The takeaways are:

- You have to measure the resistance from point to point on the floor.

- You have to measure the resistance from some point on the floor to ground.

- You have to measure the resistance that includes the person, the heel straps, and the floor.

- You must measure the floor for walking body voltage generation using the type of footwear that you plan to use in your factory or any that you think you might be using in the future.

- And those tests should be done at 12% humidity.

That’s what we call the qualification phase of testing ESD flooring.

We hope you learned something today. If you have questions about the podcast, give us a call at 617-923-2000. Even though we specialize in solving problems with flooring, if you have a question about static discharge, how to install a floor, how to test the floor, we’ll be glad to help. Thanks for listening.

Welcome to Static Talks. I’m your host, Dave Long, founder and president of Staticworx. We make static-control flooring and our podcast will discuss the threat static electricity poses to your business and how to address those risks.

Rick, remember that question this morning about the PU coating on the ESD vinyl tile?

Rick: Yes.

Dave: And the testing?

Rick: I do.

Dave: Back in 2014, the ESD Association revised a standard called ANSI/ESD S20.20 and one of the parts of that standard calls out for requirements in ESD flooring. Those requirements have to do with several different parameters. So, when we look at flooring, there are several properties we’re actually hoping we can identify so we can determine if we’re going to be able to achieve what we need to with our ESD program.

So one of the properties we look at is electrical resistance. We measure that using an ohmmeter. Historically, when flooring has been qualified and certified after installation, the method of doing that was to take an ohmmeter and take two of what we call NFPA probes, which are basically a couple of five pound weights with a rubber, elastomeric material that’s conductive on the bottom of them and we set these probes down on the surface of the flooring, and we measure the resistive properties between two probes. Then we take one of the probes, disconnect it from the ohmmeter and instead make that connection to a ground source, and measure the resistive properties from the probe that’s still connected to the ohmmeter through the flooring to the adhesive to ground. We call that test a resistance-to-ground test.

Before 2014, if the floor measured less than 10E9 – which is a billion ohms – and then we did a second resistive properties test, which amounted to standing on the floor in place of the probe… So, picture this: instead of having a probe on the floor, you’re standing with your ESD heel straps or ESD shoes, and you become the probe. So you take the test lead from the ohmmeter, you hold it between your fingers, the other lead is attached to ground, and we make a measurement that includes your body, your ESD footwear, the floor, the adhesive, all the different items that are used to make that connection to ground. So that test is called the system resistance test and that test standard ends in 97.1. So it’s ANSI/ESD STM97.1.

Before 2014, you would do these two tests. You would test the floor with the five-pound weights, and you would test the floor with a person essentially acting as a probe, and if the five pound weight test measured under 10E9 and if the system resistance – which included the person in their heel straps – measured less than 3.5 x 10E7, you would say that floor now qualifies for use in an ANSI S20.20 compliance program. That was the end of it.

Rick: But it sounds like that type of test does not actually produce a useful measurement, right?

Dave: The major downside to relying on that test is that you’re using resistive properties as a predictor of whether or not when a person walks on the floor, they’ll generate a static charge. Now, we measure static charges in volts, not ohms. So right away, we’re using a test that measures a different property, using a different unit of measurement, to predict a property that kind of has nothing to do with resistance. And I guess the way we want to describe this as it played out, we would often see conductive floors – which measure less than one megohm in any location on the floor, whether it was an epoxy floor, or whatever type of floor the client might have – but under certain circumstances, even though the floor measured in the conductive range, when a person would walk on the floor, with their ESD footwear, they would generate, in some cases, hundreds or even over 1000 volts of static electricity.

Of course, that doesn’t make sense to some people because they’re thinking if the floor’s conductive and you’re wearing ESD footwear, how’s that possible? Well, remember one thing: heel straps cover your heel. If you were to capture a person’s walking motion in slow motion, what you would actually notice is that sometimes the forefront of their foot is making contact with the floor, sometimes their heels are, and depending upon their gait, it’s even possible that for a moment in time, there’s actually no contact at all with the floor. Because of the way heel straps work – you’ve seen heel straps, right?

Rick: Right.

Dave: Okay, so a heel strap, because it’s only covering the heel, other than where the heel strap is covering your shoe the rest of your shoe is an electrical insulator. So when that electrical insulation portion of the shoe makes contact with the floor, it generates a static charge. If you happen to do that, at the same moment as you stop so that the heel strikes the floor, that charge would immediately go to somewhere – hopefully – fairly close to zero. But because walking is moving, you’re actually generating charges and, sure, they’re discharging, but you’re generating what we would call spikes of voltage.

Rick: When measuring walking body voltage, is that a measurement of the flooring itself or of the footwear worn by people in that room?

Dave: When we perform a walking body test to measure the static charge on people, one of the things we’re actually learning is not just whether the floor does what it’s supposed to do, but whether the ESD footwear that they’re using does what it’s supposed to do, and more importantly, whether the ESD footwear and the floor actually work with each other.

Over the last 15 years, we’ve been working with a third party testing lab that we send flooring to so that they can test it in a controlled environment. And by controlled environment, I mean an environment where they condition the flooring materials – and the footwear, for that matter – at 12% relative humidity. The reason for the 12% relative humidity is that in all these ESD standards that you’ll hopefully either already have, or hopefully be obtaining based on our discussion today, the first thing you will learn about flooring for removing static electricity is that you need to qualify the properties of the floor so that you can then make a decision based on that flooring working under a low humidity condition. Because when you install the floor, it’s very likely that on any given day the relative humidity could be 20% or it could be 70%, and as a result of fluctuating humidity in a lot of these factories, you could potentially qualify a floor in your factory, not in a controlled environment, on a day when the humidity is high, and assume that your flooring meets the qualification standards of the ESD Association, and not ever know that on days when the humidity is low, your flooring isn’t doing what it’s supposed to do.

The way the S20.20 document handles that potential, I guess you could say pitfall, is they want you to first qualify the floor, and by qualify they mean send it to a lab, or if you happen to have the right humidity chamber to make these sorts of tests which most people don’t have, sure you can do it yourself, but you need to know what that flooring will do at low humidity using the footwear that you plan to use in your factory. So let me just back up a little bit because this is kind of an important point.

Suppose you’re going to buy flooring, and you decide that you’re going to get brochures and literature from several different manufacturers. Every one of those brochures is probably going to have some statement or list of performance parameters that will include what we call walking body voltage and resistive properties. And if you look at the walking body voltage properties, I don’t know a flooring manufacturer in existence that doesn’t state that they meet ANSI/ESD S20.20. However, if you look more closely, what you’ll discover is they don’t tell you what type of footwear that the flooring met the hundred volt maximum of ANSI S20.20 with. They just tell you they meet it [the standard]. What we’ve learned – kind of the hard way, because like any manufacturer, we’re always trying to make sure that we stay ahead of things – is that certain footwear works better with certain floors.

Rick: Alright, so we know that even if ESD footwear is being worn consistently, the particular type of ESD footwear will have an influence over the results of your compliance testing. Can you offer any real-world examples of this?

Dave: So for example, one of the tests we did a few years ago was with an interlocking plastic floor that we thought looked like it was a very, very good product, and the literature actually stated that the floor generated less than 25 volts on a person per the ANSI test method for walking body voltage. However, when we did the test at the third party testing lab, we generated 700 volts on that floor, and the reason we were able to get 700 volts is we happened to choose to use ESD heel straps for the test. The reason we did that was, the particular customer we were doing the test for asked us to make sure that we tested the floor with the type of footwear that they planned to use. And they didn’t plan to use the ESD shoes, which actually provide a full sole contact area that has conductive properties. Like I said earlier in this discussion, heel straps only cover the heel of your shoe. So when you test the floor, you need to test it not only with the footwear that you will be using, but also the footwear you might give to a visitor.

This particular company wanted us to test it [the floor] with heel straps and we did. That 25 volts generated with a particular ESD shoe became 700 volts, not because the floor we tested was any different than the one the manufacturer tested, but because we tested it with footwear that essentially would not work with that floor. And that’s a big problem because, in my travels around the world, most companies – particularly electronics manufacturing of circuit boards and any kind of high volume electronics – they have a tendency to give their employees heel straps as their ESD footwear, not ESD shoes. So a set of heel straps probably cost somewhere in the vicinity of $7-8, a pair of ESD shoes could cost $150, and because of the obvious need to control costs, you’re going to notice that most factories use heel straps. So whenever we perform any type of testing on ESD flooring, we’re always going to be including heel straps and several different types of ESD shoes in our test so we can tell the client, this is what you can expect with this, this is what you can expect with that.

Unfortunately, when you read the literature, it doesn’t tell you that and I’m talking about anyone’s literature – ours included; otherwise the information would get too crowded. So normally when we work with a client, what we will do is we will also send them the test reports. That way they have the opportunity to look and see if they can confirm that the type of footwear they’ll be using was in that test.

The takeaways are:

- You have to measure the resistance from point to point on the floor.

- You have to measure the resistance from some point on the floor to ground.

- You have to measure the resistance that includes the person, the heel straps, and the floor.

- You must measure the floor for walking body voltage generation using the type of footwear that you plan to use in your factory or any that you think you might be using in the future.

- And those tests should be done at 12% humidity.

That’s what we call the qualification phase of testing ESD flooring.

We hope you learned something today. If you have questions about the podcast, give us a call at 617-923-2000. Even though we specialize in solving problems with flooring, if you have a question about static discharge, how to install a floor, how to test the floor, we’ll be glad to help. Thanks for listening.

Further Reading/Viewing

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

Other Podcast Episodes

Static Bursts (Ep #2): Static-Dissipative versus Conductive Flooring

Have you ever wondered why we recommend static-dissipative flooring for...

Read MoreStatic Bursts (Ep #4): Avoiding Problems When Installing ESD flooring Over Existing Surfaces

New floors are typically installed over the following pre-existing surfaces:...

Read MoreStatic Bursts (Ep #5): Hidden Costs of Flooring Installations (Part I) – Vapor in the Concrete

Moisture or vapor in the concrete subfloor can cause your...

Read MoreLearning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.