Moisture problems are the #1 cause of failed flooring installations....

Read More

Static Bursts (Ep #7): Installing ESD Flooring in a 24/7 Facility Without Disrupting Operations

Dave discusses the optimal way to install an ESD floor in 24/7 operational spaces – without adhesive or chemicals and with neither downtime nor disruption.

Installing a floor in a 24/7 operational facility comes with its own set of challenges. As with any flooring installation, it’s important to consider logistics: Will chemicals be used? Adhesives? Coatings? Are there toxins or odors to deal with? What is the condition of the current floor or subfloor? Will the old floor require removal?

Dave discusses the optimal way to install an ESD floor in 24/7 operational spaces – without adhesive or chemicals and with neither downtime nor disruption.

Episode Highlights: Avoiding Problems When Installing ESD flooring Over Existing Surfaces

To avoid problems, do your due diligence:

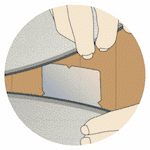

- Do a fair amount of “destructive testing”

- conduct pull tests (try to pull up old tile to check bond and see what’s underneath)

- Strip old wax from existing surface

- layers of wax can keep tiles in place, even if the adhesive bond is broken; floors installed over poorly bonded tiles will fail

- Check when old floors were installed

- were floors in all areas installed at the same time?

- Check to be sure there is no asbestos or other dangerous chemicals/materials

- asbestos requires removal per EPA standards/guidelines

Before installing a new floor:

- Confirm adhesive is intact and bond between existing floor and subfloor is strong

- Send old tiles to an independent lab for testing, so you know what you’re looking at

- Skim coat to flatten surface and fill in any gaps or seams – if the subfloor is imperfect, the new floor will telegraph those imperfections

- Do a fair amount of “destructive testing”

We’ve made it easy to subscribe on your favorite platform!

Rick: Welcome to Static Bursts, the info-packed three-minute podcast from StaticWorx, designed for a quick listen.

Dave: I’m your host, Dave Long, founder and president of StaticWorx.

Rick: Dave, how do you install ESD flooring in a 24/7 work environment without interrupting business operations?

Dave: If the job needs to be done in an occupied space that’s operational, now you’re looking at logistics like: Okay, how do we keep this operation running while we’re installing the floor? What kind of chemicals are we going to use? So in other words, are we going to be using adhesives? Are we going to be using coatings that might have an odor? Are we going to be using materials that might have cure time?

Let’s take an example like a call center for a police dispatch operation, and we’ve done a lot of these kinds of jobs. So. you’ve got an 800, sq./ft, small town 9-1-1 call center. They’ve got three dispatchers working in the room and they need to be able to get in and out of the room. So right away, you’ve got to be thinking about, “How am I going to install this floor without interrupting their important work?” Which I think we would all agree is very important. But how are we going to give these people access to get out of the room if they need to use the bathroom, if the shift ends and they need to get home from work, if a new person needs to come in, if they need to have a discussion with another person? So we need to be looking at the installation, not just from the perspective of do we have the right material, but do we have the right installation method, because if we can’t present them with a solution that allows them entry and egress without causing a problem, they’re not going to be able to do their job. So when I look at a call center application, the first thing I look at is, can I do the job without an adhesive.

Rick: So a floating floor that requires no adhesive would be a great solution for installing in an occupied space with operations that cannot tolerate any downtime, right?

Dave: So, definitely in the 24/7 operation, absolutely. If you’re going to start removing old flooring, or preparing the surface to take on some kind of an adhesive that it’ll bond to, that’s not going to work. So in those situations our usual go-to solution is to give the customer a floor that they can put together in pieces, where there’s never any downtime -waiting for adhesives to dry, dealing with the smell of any kind of chemicals that might be used for floor prep – that literally would allow in a dispatcher operation for someone to get in their chair and slide over six feet – which might require them to plug into a different console or maybe they’ve got a headset that will allow them to move that far – lift up their console, sneak some carpet tiles underneath the console, drop the console back down and allow that person to resume their position at their station.

We hope you learned something today. If you have questions about the podcast, give us a call at 617-923-2000. Thanks for listening.

Rick: Welcome to Static Bursts, the info-packed three-minute podcast from StaticWorx, designed for a quick listen.

Dave: I’m your host, Dave Long, founder and president of StaticWorx.

Rick: Dave, how do you install ESD flooring in a 24/7 work environment without interrupting business operations?

Dave: If the job needs to be done in an occupied space that’s operational, now you’re looking at logistics like: Okay, how do we keep this operation running while we’re installing the floor? What kind of chemicals are we going to use? So in other words, are we going to be using adhesives? Are we going to be using coatings that might have an odor? Are we going to be using materials that might have cure time?

Let’s take an example like a call center for a police dispatch operation, and we’ve done a lot of these kinds of jobs. So. you’ve got an 800, sq./ft, small town 9-1-1 call center. They’ve got three dispatchers working in the room and they need to be able to get in and out of the room. So right away, you’ve got to be thinking about, “How am I going to install this floor without interrupting their important work?” Which I think we would all agree is very important. But how are we going to give these people access to get out of the room if they need to use the bathroom, if the shift ends and they need to get home from work, if a new person needs to come in, if they need to have a discussion with another person? So we need to be looking at the installation, not just from the perspective of do we have the right material, but do we have the right installation method, because if we can’t present them with a solution that allows them entry and egress without causing a problem, they’re not going to be able to do their job. So when I look at a call center application, the first thing I look at is, can I do the job without an adhesive.

Rick: So a floating floor that requires no adhesive would be a great solution for installing in an occupied space with operations that cannot tolerate any downtime, right?

Dave: So, definitely in the 24/7 operation, absolutely. If you’re going to start removing old flooring, or preparing the surface to take on some kind of an adhesive that it’ll bond to, that’s not going to work. So in those situations our usual go-to solution is to give the customer a floor that they can put together in pieces, where there’s never any downtime -waiting for adhesives to dry, dealing with the smell of any kind of chemicals that might be used for floor prep – that literally would allow in a dispatcher operation for someone to get in their chair and slide over six feet – which might require them to plug into a different console or maybe they’ve got a headset that will allow them to move that far – lift up their console, sneak some carpet tiles underneath the console, drop the console back down and allow that person to resume their position at their station.

We hope you learned something today. If you have questions about the podcast, give us a call at 617-923-2000. Thanks for listening.

Get in Touch

The form below will help us better understand your needs and get you as quickly as possible to the right person. We look forward to helping you solve your static problem!

You can expect a response within 24 hours. For faster service, please give us a call: 617-923-2000

"*" indicates required fields

Visit our privacy policy to find out how we process data.

Other Podcast Episodes

Static Bursts (Ep #2): Static-Dissipative versus Conductive Flooring

Have you ever wondered why we recommend static-dissipative flooring for...

Read MoreStatic Bursts (Ep #3): Why Resistance Tests Alone Are Not Enough to Properly Qualify An ESD Floor

How can you predict whether an ESD flooring material will...

Read MoreStatic Bursts (Ep #4): Avoiding Problems When Installing ESD flooring Over Existing Surfaces

New floors are typically installed over the following pre-existing surfaces:...

Read MoreLearning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.