Glossary: Minimum Resistance

The ANSI/ESD S20.20 static control standards does not offer a minimum resistance reading. Strictly in terms of grounding static charges, any floor with a resistance <1 x 10E9 meets ANSI/ESD S20.20 and is considered acceptable.

While S20.20 does not specify a lowest acceptable resistance, for best practices the flooring industry has historically set the minimum resistance at no less than 2.5 x 10E4, or 25,000 ohms. This number was based on a defunct NFPA test method, requiring a resistance test with 500 volts of DC current applied to the surface of the flooring material. Current standard test methods apply much lower voltage and yield higher readings.

A floor measuring 25,000 ohms using the NFPA test method would yield a far lower resistance reading with less applied voltage.

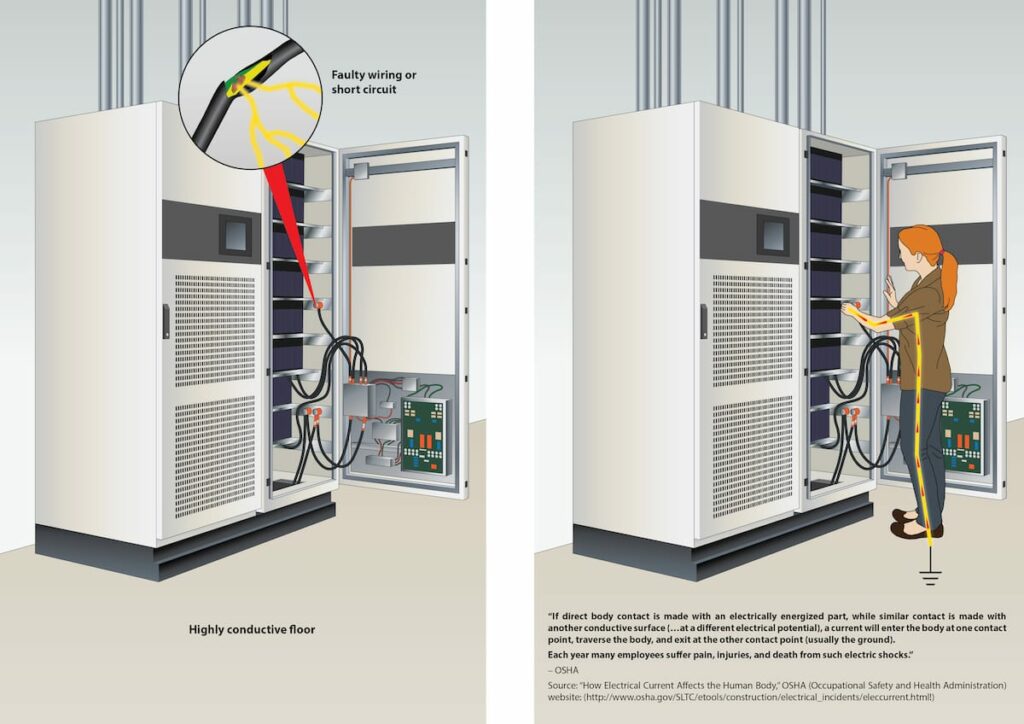

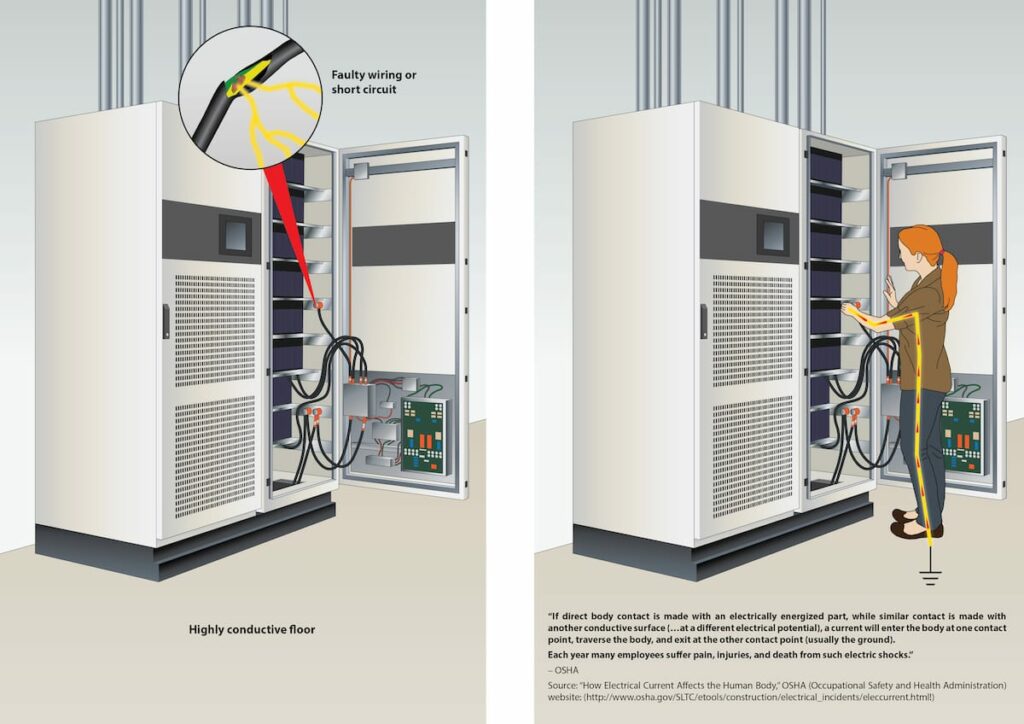

ANSI/ESD standards do not offer a minimum resistance requirement because the built-in resistor in the ESD footwear required in manufacturing and handling spaces protects the wearer from potential electric shocks. In data centers, call centers, FAA flight towers, 9-1-1 dispatch centers, and other spaces where ESD-protective footwear is not required, materials with electrical resistance below 2.5 x 10E4 are considered a potential safety hazard.

For this reason, telecom and Federal Aviation Administration standards prohibit the use of flooring materials with resistance below 1 x 10E6 in spaces where energized equipment is used.

Learning Center Articles

- ESD Basics

- Installation & Maintenance

- Selecting & Specifying an ESD Floor

- Technical Information

- 7 Common Mistakes Selecting an ESD floor

- A Guide to ESD Flooring Selection

- Avoid Costly Failures: What You Need to Know When Specifying ESD Flooring

- Choosing ESD Flooring for:

- ESD Footwear: What Is It and When Is It Necessary?

- ESD Footwear for Electronics Manufacturing and Handling Applications

- Facility Managers’ Guide to Selecting ESD Flooring

- The Need for Due Diligence in Specifying Static-Free Flooring

- Standard of Care for Specifying Floors in Mission-Critical Spaces

- Understanding the Hidden Costs of ESD Flooring

StaticWorx high-performance static-control floors protect electronic components, explosives, and high-speed computers from damage caused by static electricity. ESD flooring is part of a system. Choices should always be based on objective, researched evidence. When you partner with us, we look at all possible items that may need to integrate with the floor, and, focusing on your goals and objectives, help you find the right floor for your application.